Where does the food & drug your family eats come from? How did it get to your supermarket and grocery store? What route did it take to get there? Does it contain anything your family member is allergic to? Do these questions pop up in your head? Do such questions affect your purchase and if they do, where is the answer to these?

What is Traceability in FMCG?

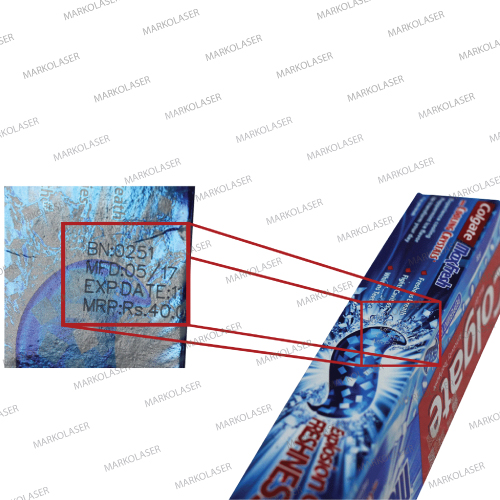

The concept of traceability answers all these questions. Traceability is documentation from ‘cradle to death’ of any product. Traceability in FMCG allows distinguishing the manufacturers of different brands alongside tracing and tracking various details such as where and when it was manufactured, country of origin, date and time of production/manufacture, processing details, constituents details, name of the manufacturer, distributor, supplier, model, expiry date, etc.

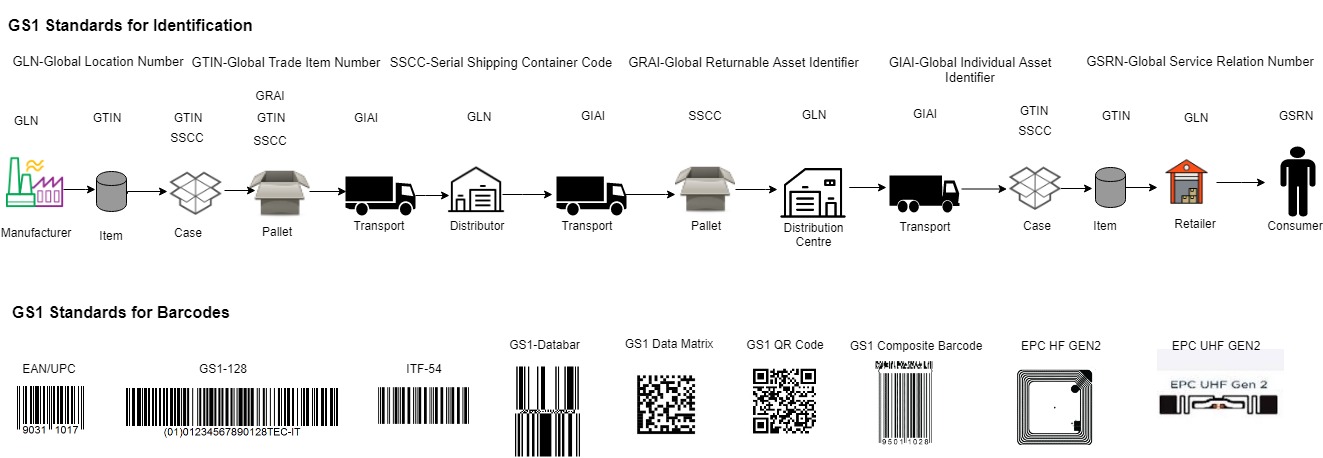

There is a raging strictness in the compliances over the last couple of years. Many government legislators, in various countries such as Europe and the United States, have been drafting laws requiring various degrees of traceability, especially in the FMCG industry. GS1 standards are widely used in the retail and FMCG sector and India being a vast country with FMCG as its fourth-largest sector is witnessing traceability norms and regulations rapidly pouring in.

Need for Traceability in FMCG:

- Stringent norms and regulations imposed by the regulators.

- Ever increasing expectations of consumers in terms of quality and safety standards.

- Hedging the risk of recalls and reducing the liability costs.

- Curtailing intentional or unintentional adulteration, health epidemics, and environmental emergencies.

- Maintenance of records and database.

- Curbing the problem of counterfeiting and providing authentication.

- Informative supply chain, reduced waste, novelty and increased efficiency in business processes.

Samples at a glance

Laser marking

Laser marking

Laser marking

Laser marking

Laser marking

Laser marking

Traceability has different meanings for different stakeholders. For public safety, traceability is all about curtailing intentional or unintentional adulteration, health epidemics, and other environmental emergencies. In the case of businesses, it is about hedging the risks of recalls and cutting down the liability costs. In the supply chain, traceability adds information, provides ways to improve the efficiency of business processes, reduces wastes. And for consumers, traceability is knowing the inside out of whatever they are consuming. Regardless of a specific reason, traceability is critical to all stakeholders.

What Markolaser offers?

At Markolaser, we specialize in providing traceability solutions to link your raw material to your final product, allowing the tracking through each and every stage of production, processing, storage, distribution, and consumption.We integrate the tracking of source inputs like raw materials, additives, packaging, etc. Markolaser solutions will allow FMCG companies to get better in product quality, optimizing production, and achieving customer confidence and faithfulness.

For more details visit us at

Email us:

info@markolaser.com

Check-out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For the jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |