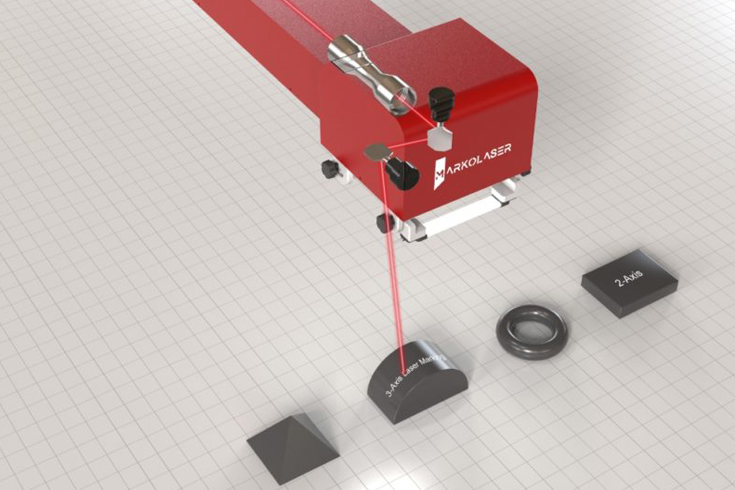

This recommendation letter is with respect to a *3D Texturing Laser machine”(3axis laser marking machine) procured by National Institute of Technology Srinagar, Under TEQIP II from Mr. Vineet Jain (M.D) of M/S Spinks Impex, MARKOLASER, a Laser manufacturing company in Gurgaon. The machine was initially procured to conduct 3-Dimensional texturing exercises on samples like Silicon […]

Many Congratulations to Dr. Vivek Bhardwaj IIT Delhi : Thank You MARKOLASER

Spinks World is pleased to announce that its Markolaser- laser marking machines are being used by research students in various IITs for distinct research projects in engineering departments. One such Research activity of Dr. Vivek Bhardwaj, of IIT, Delhi has been published. Dr. Vivek has been very kind to have acknowledged our laser marking machines […]

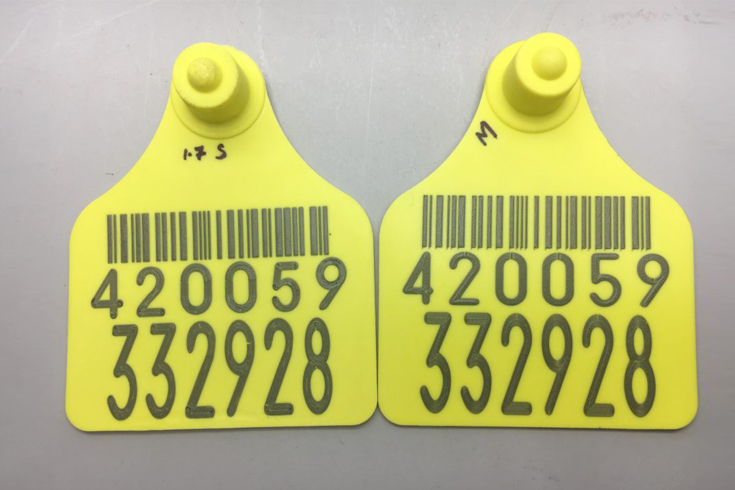

Smart livestock Identification|Laser marking machine| Markolaser

It’s not just humans that have to deal with epidemics. Animals must face a host of diseases, from Ebola to corona and even the plague . Identification of livestock becomes an utmost necessity of the present market. Laser marking machine is required for barcoding on animal tags to identify the right animal and to trace […]

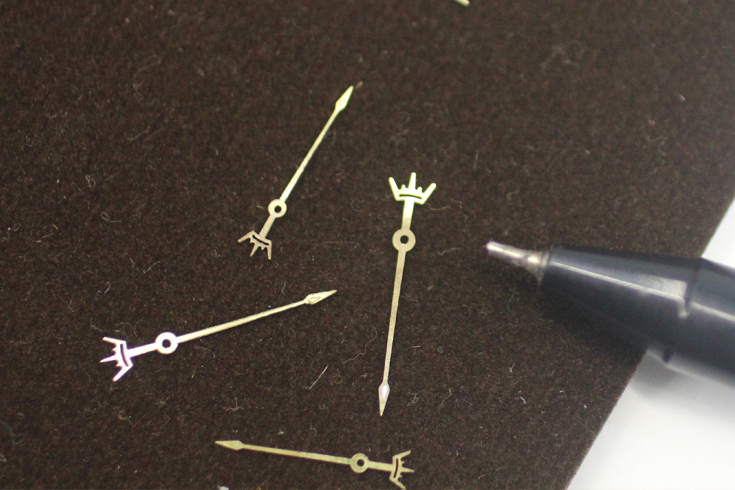

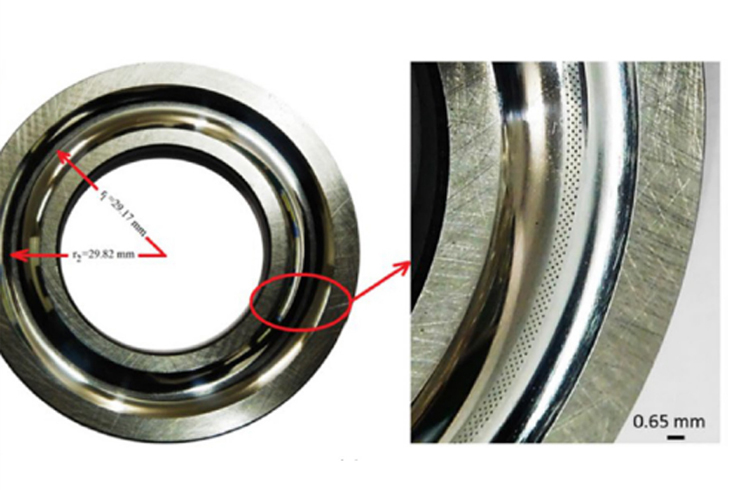

COMPARISON OF FINE SAMPLE CUTTING USING FIBER LASERS

A comparative study was done by cutting fine samples of watch needles on a sheet of brass of thickness 1.2 mm using 20W and 50W fine fiber lasers. The primary reason behind this study was to determine the effectiveness and unparalleled results of fine sample cutting and hence the effects upon post-processing. Two fiber lasers […]

Under Ultrasonic Soap Water Laser Marking [automotive industry]

We at Markolaser conducted an experiment in our R&D lab. The experiment was about laser marking on the metal strip inside an ultrasonic cleaning soap liquid which was placed at 10 mm distance in a dish. The markolaser machine can do in-depth marking in liquids up to a limit of 250 mm. This is particularly […]

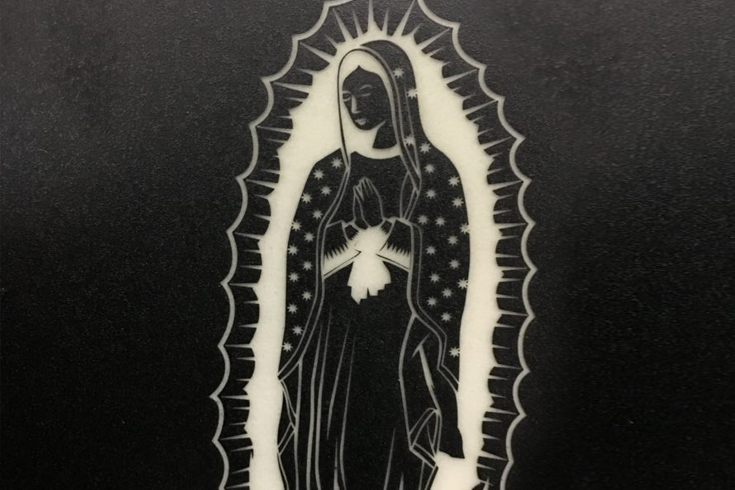

Laser marking on black ceramic

Laser marking on ceramic is usually a tedious process due to the fact that the thick paint that persists over the ceramic needs to be removed to make the necessary artwork and designs. Conventionally, carbide tools are used for engraving the surface by merely removing a layer of the paint. This may cause anomalies like […]

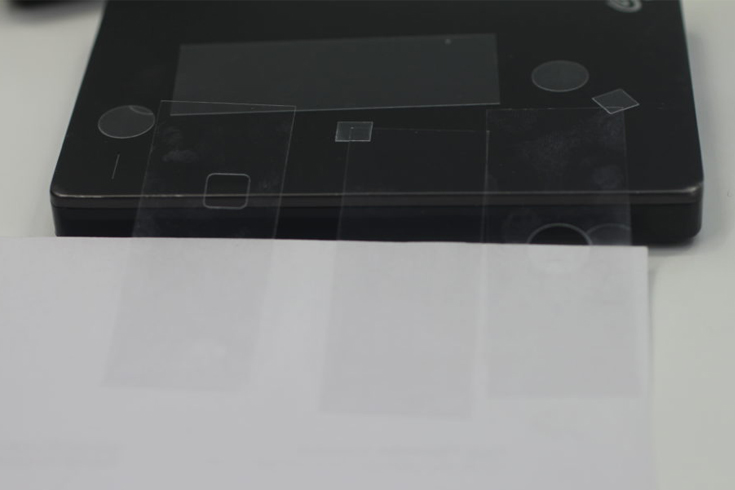

Glass Scribing Laser Solution

Glass micro slides and Graticule slides Laser solution marking for glass and glass micro slides made exactly of fused quartz or either borosilicate glass are used for characterization and sampling purposes. Plain slides are often used for holding liquid or powder samples under microscopy devices. The thickness of the slide varies according to the ultraviolet […]

Watch parts laser cutting

Situation: Cutting out fine structures of watch parts from brass and aluminum alloy sheets (thin in thickness) with a laser cutting machine. Laser marking on watch parts is quite complicated in design and requires utmost precision in machining due to the fact that parts are very tiny. Distortion of the parts by even most minimal […]

![Under Ultrasonic Soap Water Laser Marking [automotive industry]](https://www.markolaser.com/blog/wp-content/uploads/2021/10/Under-Ultrasonic-Soap-Water-Laser-Marking-automotive-industry.jpg)