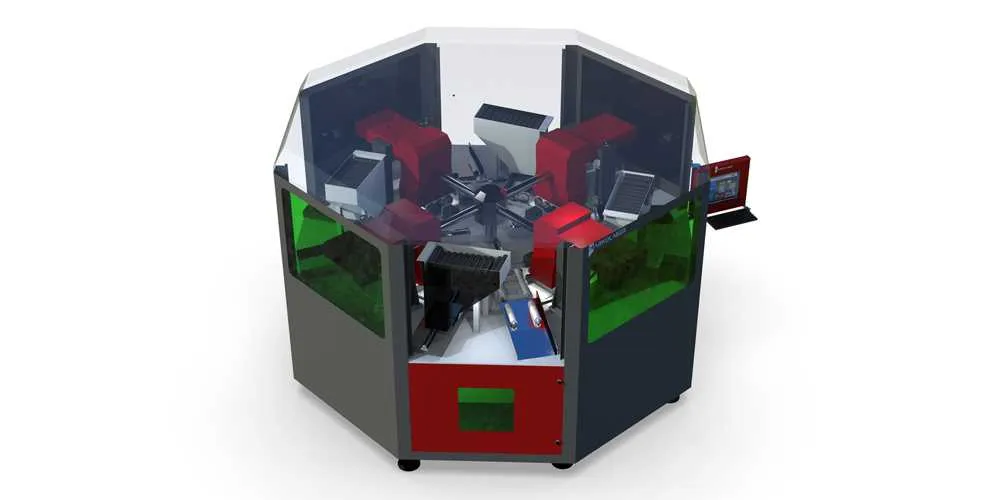

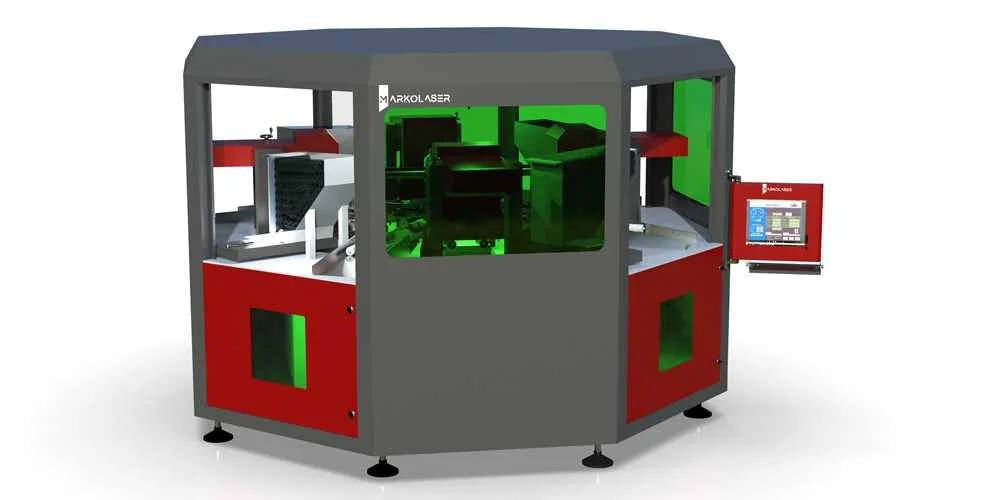

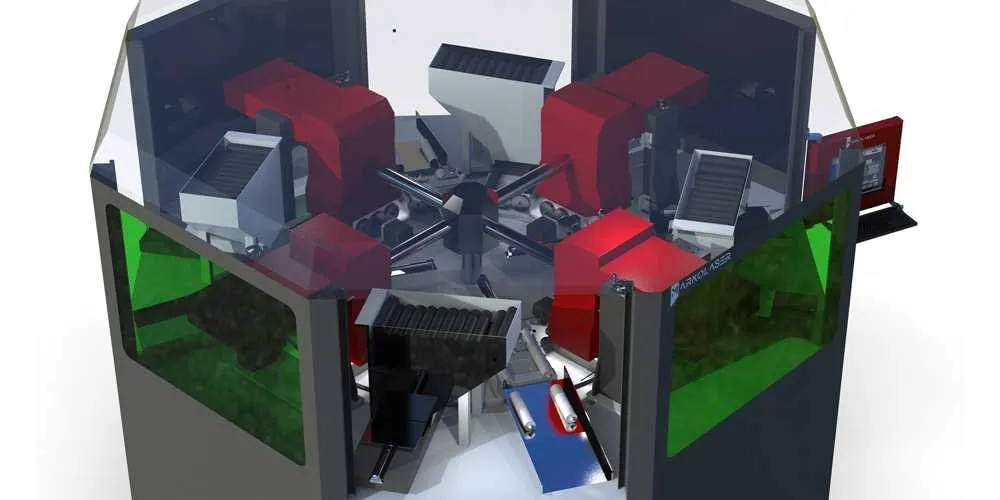

Hybrid Machine for Bathroom Fitting Industry

Pad printing & laser marking solutions

Introducing a Cutting-Edge Automation System that Integrates Dual Color Pad Printing & Laser Marking—A Seamless Solution Designed to Elevate the Branding & Aesthetics of Bathroom Fittings. Our Machine Ensures Superior Print Quality, Permanent Laser Markings & Optimized Production Efficiency, Making it the Ultimate Choice for Manufacturers Seeking High-end Finishing Solutions.

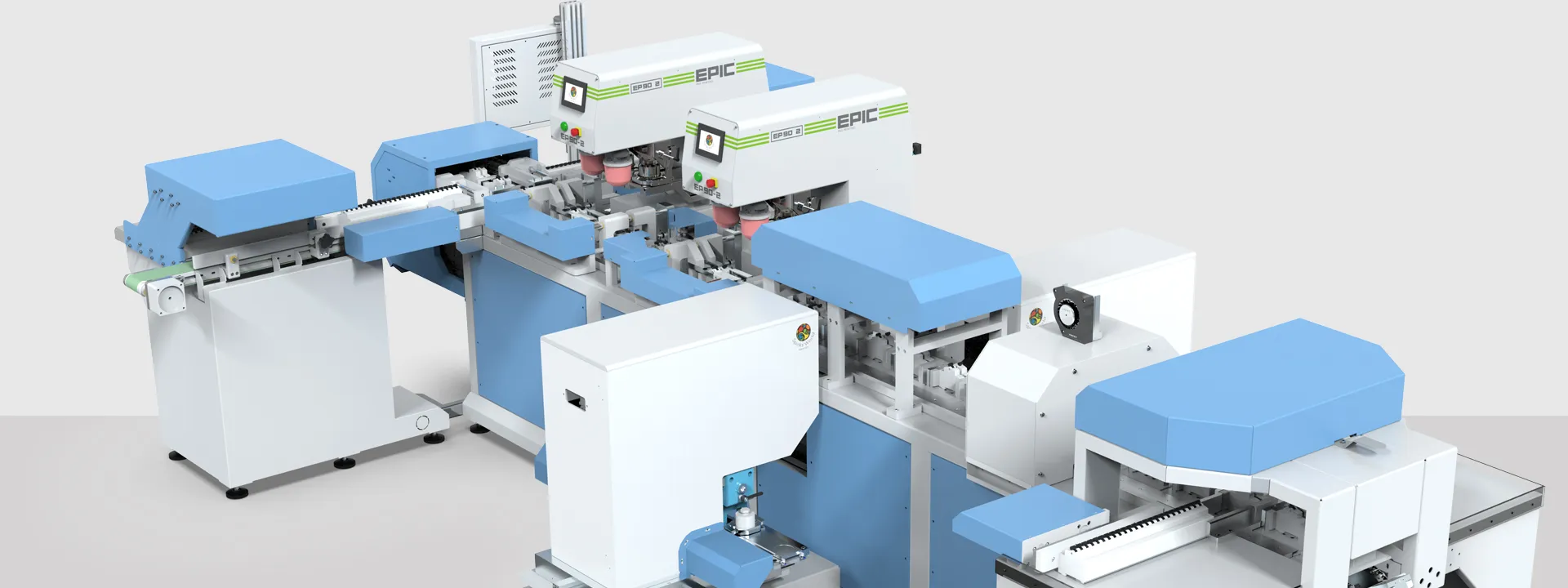

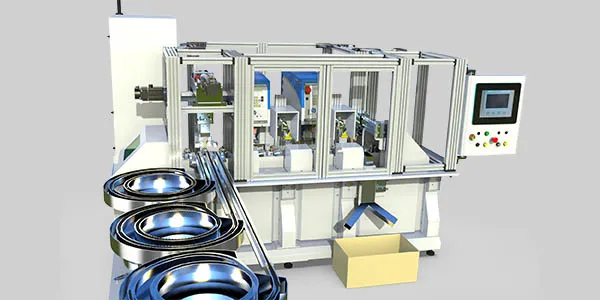

Automation for Circuit Breaker MCCB, RCCB, MCB Printing, and Marking

Industrial automation specifically tailored for the switchgear industry like MCB, RCB, MCCB, ELCB, RCCB, and RCD. Our bespoke solutions are not just machines; they are a leap towards efficiency and precision.Our universal hybrid automations are designed to cater to a wide range of switchgear manufacturing needs, making them a versatile choice for any production line

Fully Automatic Laser Marking, and Cutting Solution for Labels, Tapes

We at Markolaser provide reliable laser marking and cutting solutions for labels. Laser label markers allow precise marking of labels on different sized labels straight from the roll and cut them out without employing additional tools.

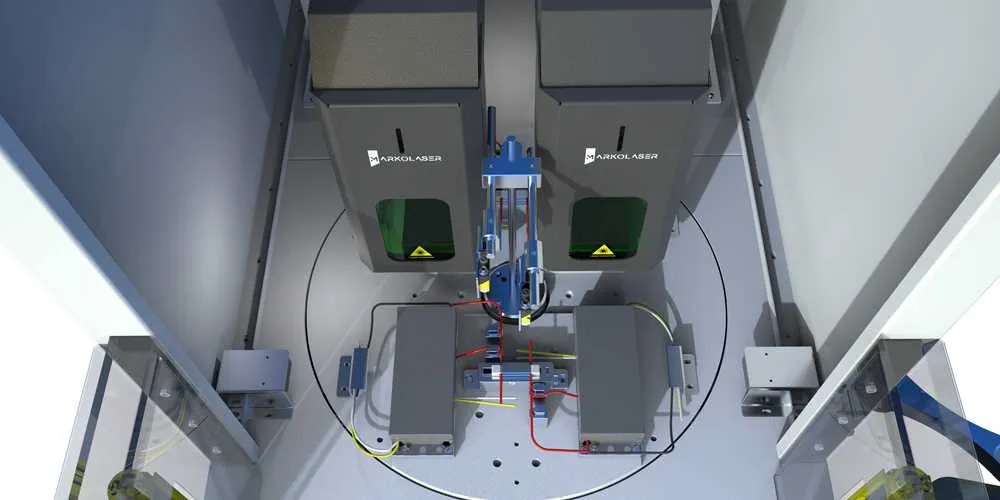

Fully Automatic Dual Head Laser Marking System on ACBs (Air Circuit Breakers)

An Air Circuit Breaker (ACB) is an electrical device that provides protection against overcurrents and short-circuits. This classic case requires laser marking of validated electrical data on two opposite faces (top and side) of the special plastic surface. Our unique solution comes with a customized client control interface that synchronizes variable data from a central server to the marking system. The user-friendly GUI provides information about real time events/alarms/live status of the machine. And, the sophisticated dual laser marking heads come with extremely specialized optical configuration, optimized to create good, fast and legible marking effects on special plastic materials.

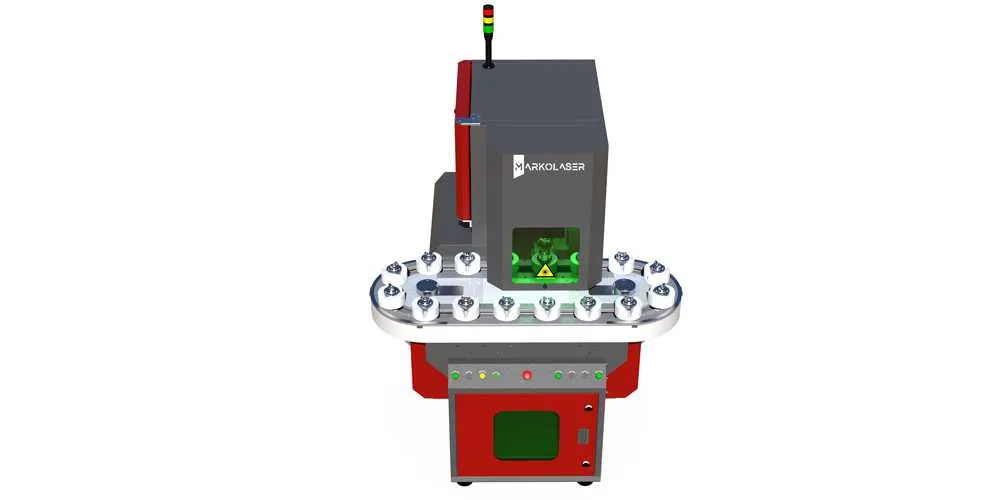

Marking on Parking Sensors

This marking solution involves a 4-station rotary table with a vision solution to mark on parking sensors. The criticality of the problem lies in the fact that marking on a parking sensor is done in multiple colors (around 42 colors). Our solution comes with an intelligent vision system which allows laser marking on the right sensor in a predefined color matrix.

Fully Automatic Laser Paint Removal from Printed Silicon Tubes

This machine is used to remove paint from plastic materials so that plastic can be recycled. The paint is collected in a dust collector and further incinerated in toxic waste. Its silicon non-disposal tube can also be reused. We have built a conceptual automated machine to clean the silicon tube.

Data Matrix Code Marking on Engine Push Rods - an Automotive Part for Traceability

This machine is engineered to laser mark a Data Matrix Code (DMC) on engine push rods .It has auto-focusing system, meticulously designed complex fixtures, tooling to accommodate numerous part-variants that facilitate fast & convenient loading/unloading of the parts by operators.

Laser Marking of Data Matrix Codes on Automotive Gears for Traceability

This is an outstanding example of a complete "Traceability Solution". This semi-automatic machine laser marks and verifies the marked data matrix code on all gear transmission assembly parts. Additionally, it is equipped with an integrated traceability system, MTM Track , a user friendly track and trace control software indigenous to Markolaser, specially customized for the project. M-Track links multiple processes and factory floor hardware, synchronizes recorded data from the server to the laser marking system, makes use of a vision code reader to verify the marked data and generate the reports.

Laser Marking on (Electrical) LED Drivers

It is a semi-automatic machine to mark on black painted housing of LED drivers. This automation consists of a dual laser head for marking and an intelligent customized interface that enables the machine to judge the part’s orientation and consequently, perform the right marking. Our specialized machine also comes with a complete range of trace and track features.

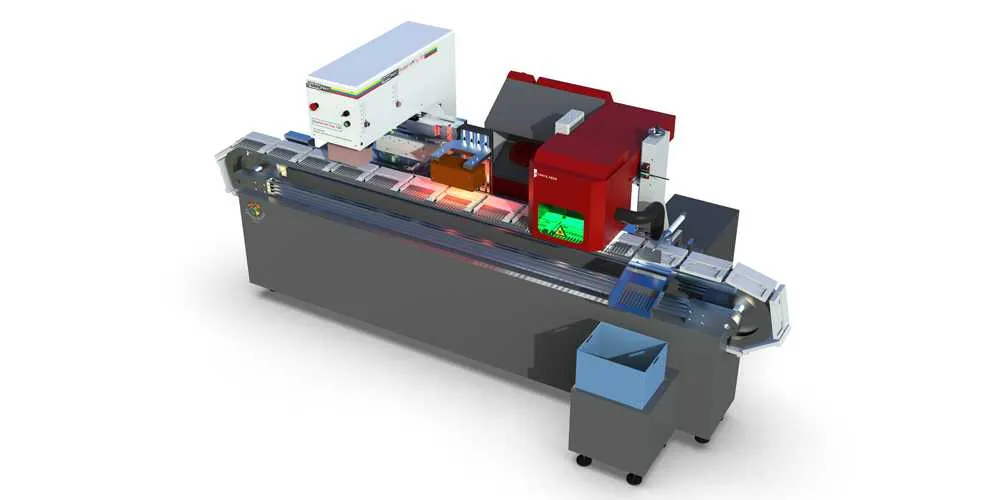

Fully Automatic Laser Marking, and Cutting Solution for Labels, Tapes

The laser label marker ensures precise marking on different sized labels straight from the roll and cuts them out without employing additional tools. After the marking, tapes can be separated by a cutter or externally rewound .A vision camera is employed between the marker and the cutter for code quality.

Print and Laser Hybrid Solution for Container Tags

This high speed, semi-automatic 'HYBRID' solution comes with automatic unloading and uses two print technologies i.e., pad printing and laser. First, a white patch is printed on a container tag by the pad-printing process then via laser processing, a permanent, high contrast, beautiful linear barcode is generated.

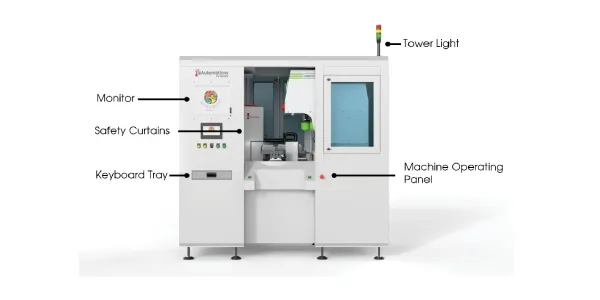

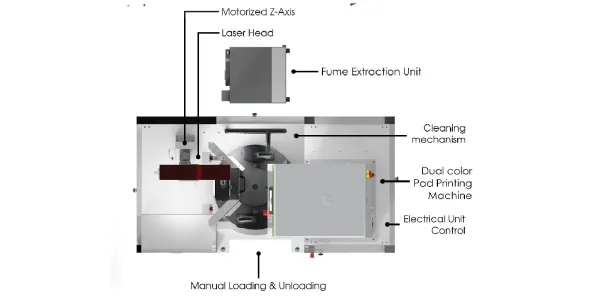

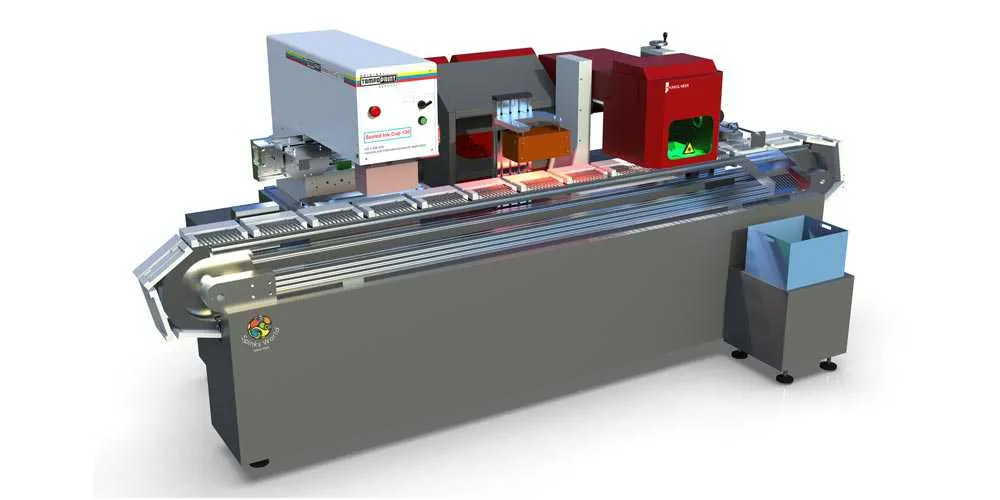

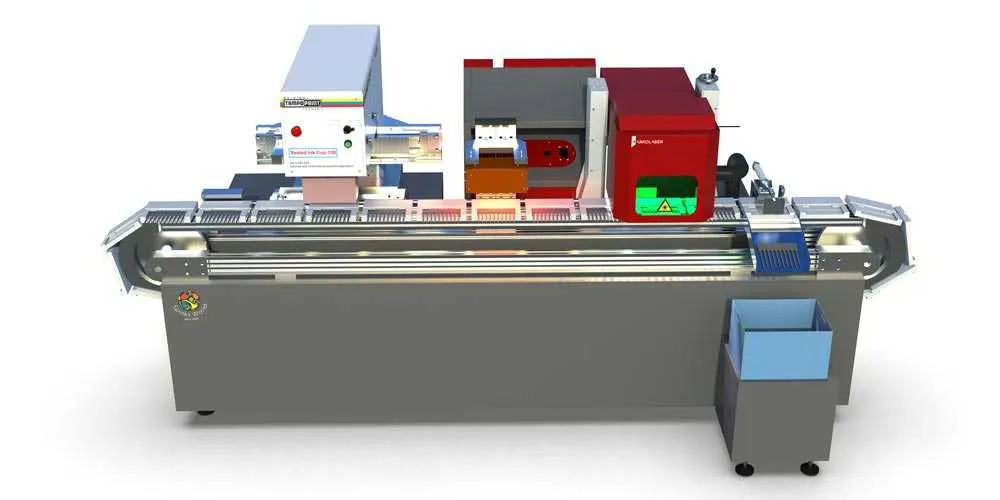

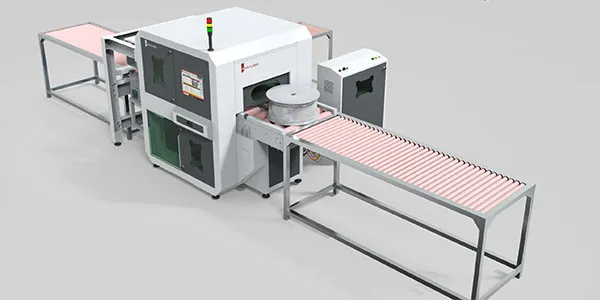

Fully Automatic Hybrid Machine (Laser Marking and Pad Printing for MCB)

This is a fully automatic pad printing and laser marking machine. In this automation, a pad printing machine prints on 3 positions with 2 colours. A laser marking head is employed for marking MCB ratings on its two sides.

SEMI-AUTOMATIC LASER MARKING & VERIFICATION OF NAMEPLATES

- Automatic laser marking and verification

- 2-position indexing tables for simultaneous load/unload and laser marking/verification

- Interchangeable fixtures to accommodate different part variants

- A separator placement module for segregation of nameplates as per the MO.

SEMI-AUTOMATIC LASER MARKING & AUTO INSPECTION AND REJECTION OF Wheels

- This is a linear PU roller wheel transport system with a wheel centering mechanism to place all the wheel variants at the center.

- It places the laser head below the conveyor/wheel with an auto X & Z-axis to mark in the inner surface area of the wheel

- A camera module is integrated to inspect the unmarked/improperly marked/inconsistently marked wheels. Such wheels are rejected and unloaded separately.

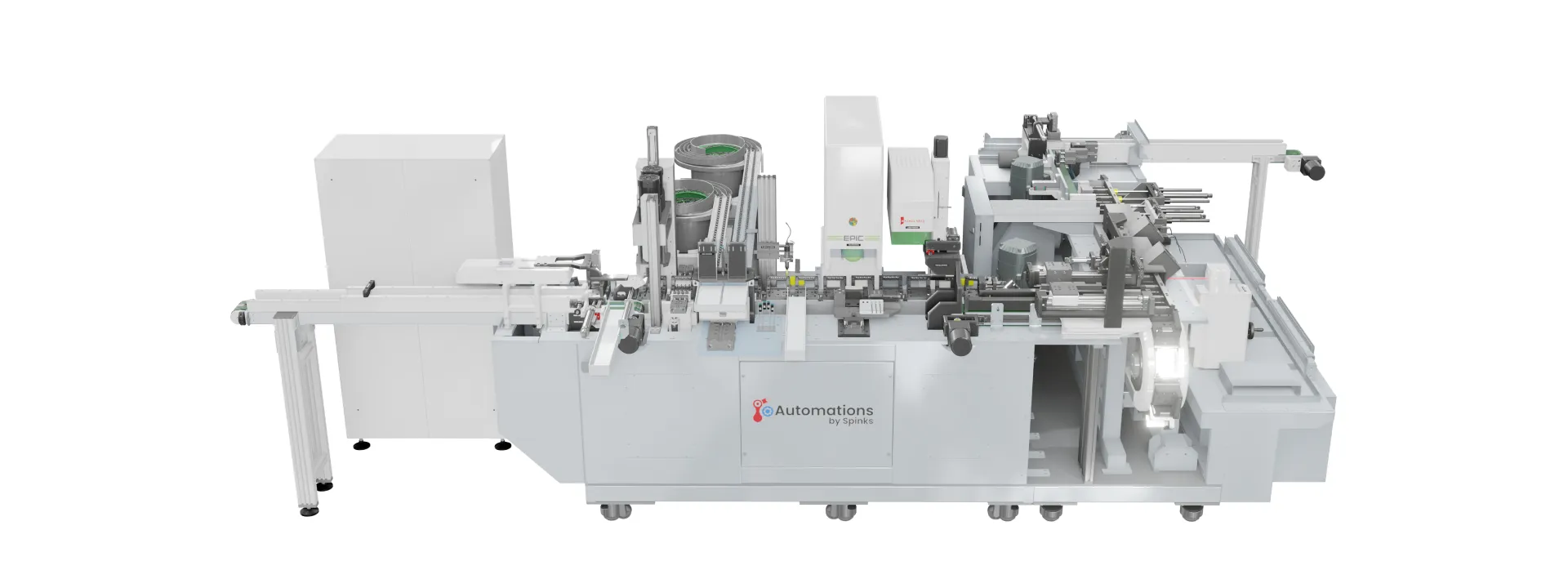

Fully-automatic toggle printing solution

Accommodating the three variants, our engineering design team has designed a common fixture for all variants.To avoid the changeover time, we have designed a unique feeding system with three feeding modules (one for each variant) synched with a pick & place module.

A vision camera module is integrated with the system to inspect the printing quality & tolerance limit. As per the feedback of the camera module, the rejected toggles and consistent quality toggles are collected into separate boxes.

Stages of Automation

-

Stages First Customer requirement with constraints and specification

Our technical sales team helps our customers by providing them with the best solutions for their machine related issues. -

Stage SecondProblem analysis

Our Technical Sales Engineer examines a project thoroughly, identifies further constraints and considers all the relevant alternatives and selects the best alternative. -

Stage ThirdConceptual design

Our Technical Sales Engineer provides a conceptual design of the required Semi/ fully automatic system that includes the component feeding system, part handling system, transportation system, loading & unloading system required for the specific problem. -

Stage Fourth Detailed design

We as a team work together to bring innovation on the desk. We design with perfection according to the customer's requirement. We rigorously do R&D to bring out the most economical and reliable detailed design. A detailed design analysis and simulation makes our design unique.Stage FifthResearch & development's

Our R&D team strives for excellence in machining; hence a thorough fundamental of industrial machining and sound experimental mind is all that is needed. Our Team continuously endeavors to make laser application projects run flawlessly and provides solutions to the most complicated of customer requirements.Stage SixthMachine building

With the use of high quality CNC and milling machine we shape every part of the automated machine perfectly.