Frequently asked Questions?

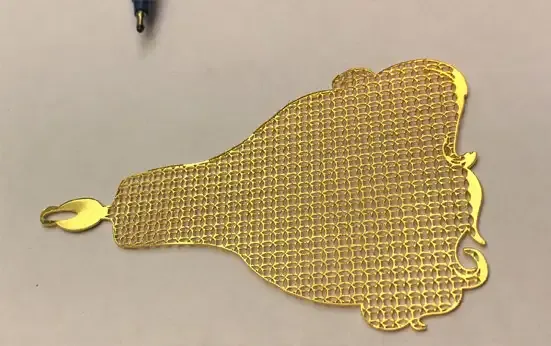

Ans: A 3D laser engraving machine allows for engraving designs with depth and dimensional detail on a variety of surfaces. Unlike traditional flat-surface engraving, 3D engraving creates multi-level surfaces, textures, and sculpted patterns. Markolaser is ideal for deep cavity molds, jewelry, customized trophies, and intricate branding applications. These machines work well on metals, acrylic, and glass, and can also create high-relief artwork. Combined with specialized software, Mtrack other software, the operator can convert 3D CAD files into precision-engraved surfaces for both industrial and artistic uses.

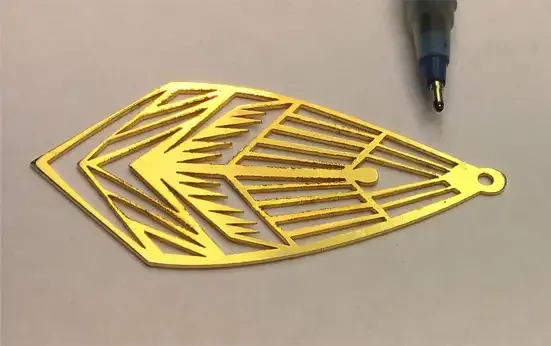

Ans: Laser cutting offers superior speed, precision, and flexibility compared to traditional methods like punch pressing, EDM, or plasma cutting. It allows for smaller kerf widths, cleaner edges, and the ability to cut intricate designs without physical contact. Markolaser’s fiber and CO₂ laser marking machines minimize fixturing needs, support automation, and are ideal for high-volume production across metal and non-metal materials, making them more cost-effective for complex jobs.

For More Information Contact :- info@markolaser.com