Manufacturing tyre dies is a critical process. It involves structuring, forging and contouring of the metal right from the melt to the final stage where the rubber is poured in to vulcanize and form the final finished product. One major point to be noted is the fact that the tyre die is unique for all manufacturers, but the method of vulcanizing and forming the finished product remains almost the same.

One key requirement in such manufacturing units is traceability. In this century, with skyrocketing production, flourishing market places, booming businesses, we have trillion-dollar economies emerging across the globe. And, as the technology further continues to progress exponentially, barriers to entry, commercialization, and knowledge are vanishing. The surfacing of more complex ecosystems of players across the budding array of manufacturing value chains and businesses is making the manufacturing landscapes evolve. Against this backdrop, parallel adversity is arising where it is getting more and more difficult to manually keep track of tons of manufacturing occurring on a daily basis and thus making it imperative to track. The goal is to tap extensive information on each manufactured unit.

The engraving of manufacturer’s details such as where and when it was manufactured, country of origin, date and time of production/manufacture, processing details, name of the manufacturer, distributor, supplier, model, etc. All these details need to be recorded on the dies and due to the modularity of laser systems, engraving of all these details is done with ease.

Machine vision with laser marked QR codes, 2D data matrix codes, numeric and alphabetic serial codes, barcodes are the future of manufacturing.

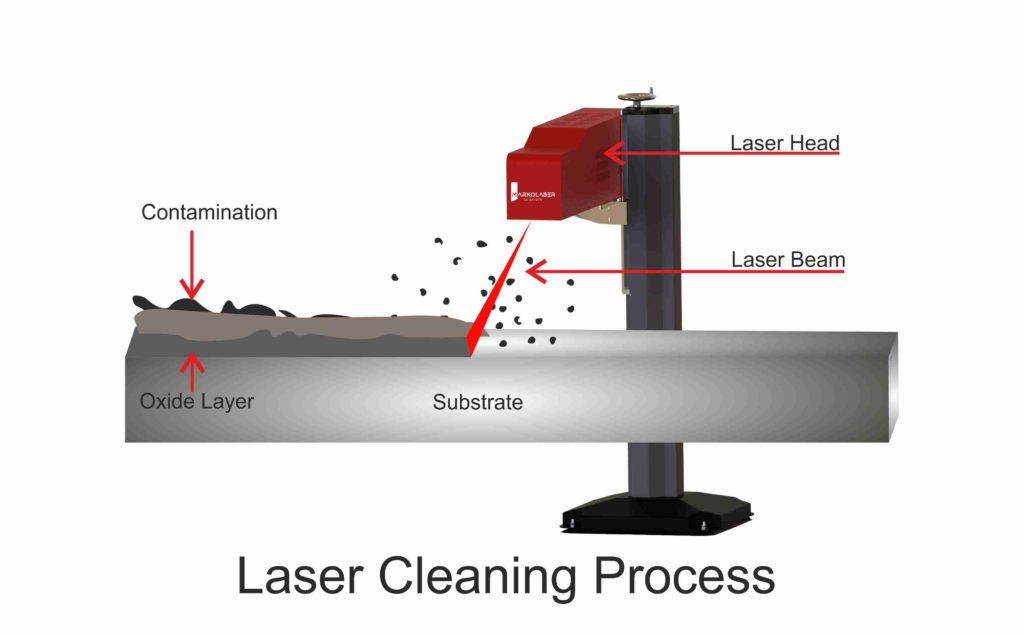

We at Markolaser, provide laser solutions to you for engraving on tyre dies. This laser application technique uses a laser to clean the surface of the substrate before it is engraved upon. Powerful, short-pulsed laser beams clean the substrate’s surface to get rid of any impurities, layers of oil, oxide, dirt or debris. Laser cleaning is the newest and a cost-efficient way of industrial cleaning these days. Ablation threshold values are different for the metal and the contamination. These variances in the ablation threshold allow for easy removal of the top layer using lasers. Lasers are very selective in removal.

Removal of top layer is done in 2 ways:

- Topmost layer is scrapped for removal of any accumulated debris or contamination.

- Topmost layer is removed to make the surface smooth and ready for engraving.

No consumables, added solvents or chemical products are used in the process. Only the laser beam is focused on the surface to vaporize the layer that is to be removed, thus making it an environment-friendly solution. Laser cleaning is often the solution when intricate designs or textured surfaces are to be cleaned. Laser cleaning saves us the setup time and can be installed quickly without much hassle.

Another difficulty manufacturers often face is that different countries have different codes & criteria to be engraved onto the dies. Thus, a previously manufactured die would not serve the purpose. One method would be to reforge the die from the melt. It would take countless hours of production and halt the manufacturing process until the final die is done. An alternative approach that we use here at MARKOLASER, is to fill the previously done engraving. Later, we engrave the currently needed criteria onto it. Lasers assist this process by providing just the push needed to complete the new die with minimal manufacturing or production time lost.

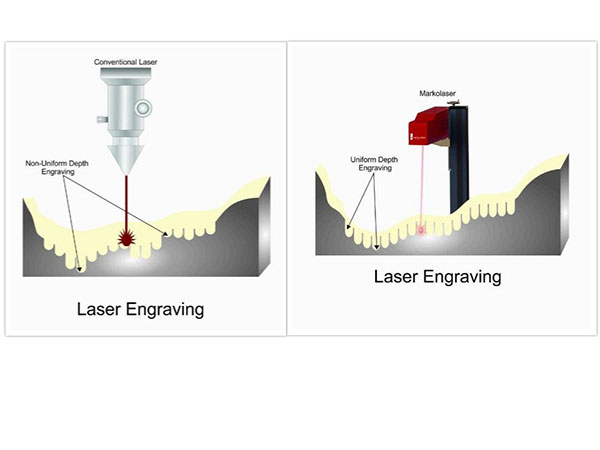

Also, MARKOLASER utilizes its 3-axis fiber laser system to engrave curved and free form surfaces, as well as the edges and contours of the tyre, die ensuring that all the engraving is done at a single time (without hindering the position of the die) as per the requisites of marking for the current procurer of the tyres. The ability of 3-axis lasers to quickly adjust their focal distance lets them engrave on odd slants and curves without any hassle. The laser beam moves back and forth across a small distance and focuses energy. This auto-focusing allows these 3-axis fibre lasers to cover a wide variety of surface shapes. Our high power lasers engrave on 3D surfaces with uniform depth on nearly any shape.

Conventional Laser engraving on 3D surface ——————— Markolaser engraving on 3D surface

For more details visit us at

Email us:

info@markolaser.com

Check-out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For the jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |