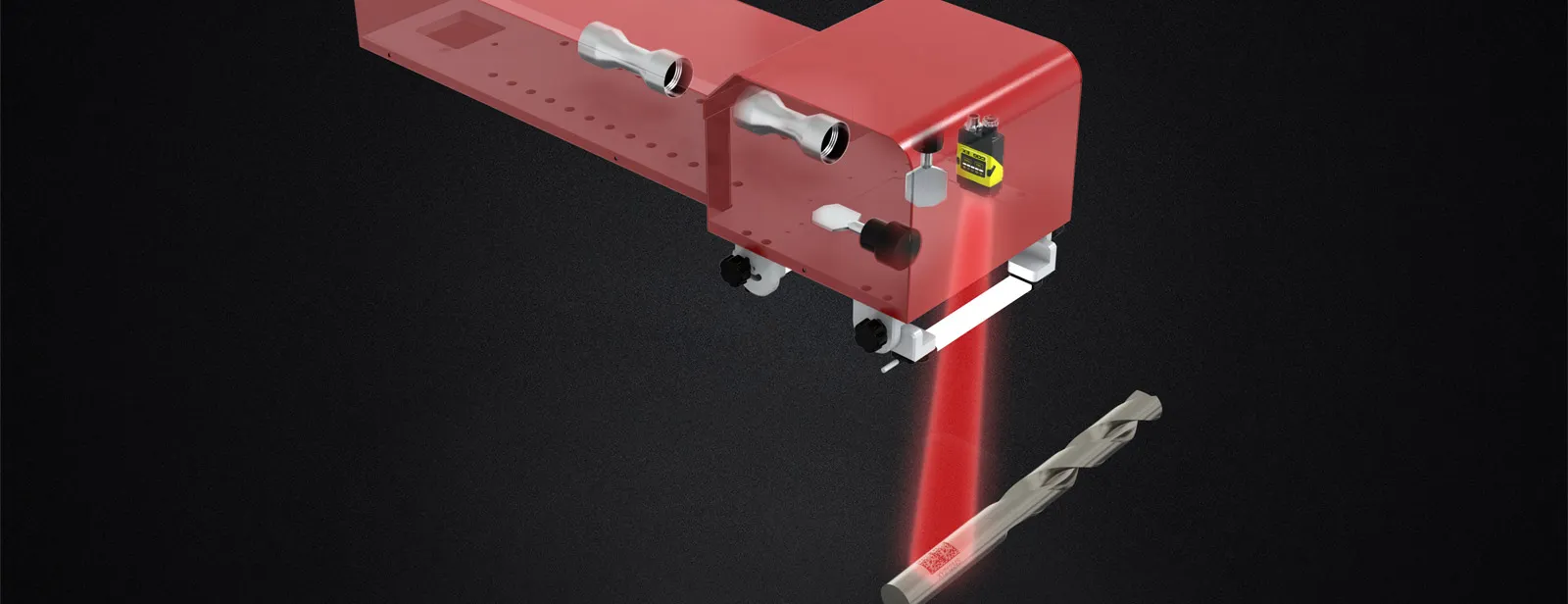

Laser Engraver for Tool Traceability, Serialization & DPM on Bits and Tools

Data Mapping

Directories of tool bits production, documentation and data mapping

Matching

Matching of tools bits with tool adapters which have industrial RFID identities and with tool presetters

Warranty

Warranty of the components can be controlled

Analysis

lifetime analysis in communication with CNC machine manufacturer

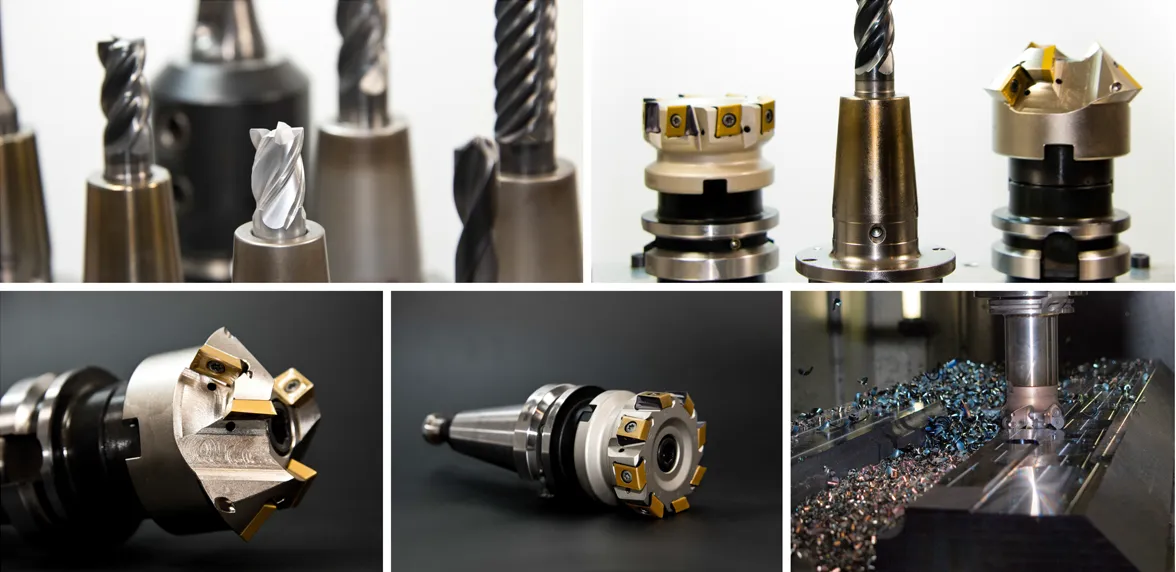

Applications

Rotate . Mills. Drill

Holders . Cutters . Collects . Tapholders

All the types of metals tools bits, fitter, opener, wrench, screwdrivers, cross wrench, and shocker wrench are made up of SS. These tools go through intense, robust industrial environmental conditions. Therefore, these tools are marked with serial code, brand logo, measurement tech specifications, size of the tool and a unique identification mark.

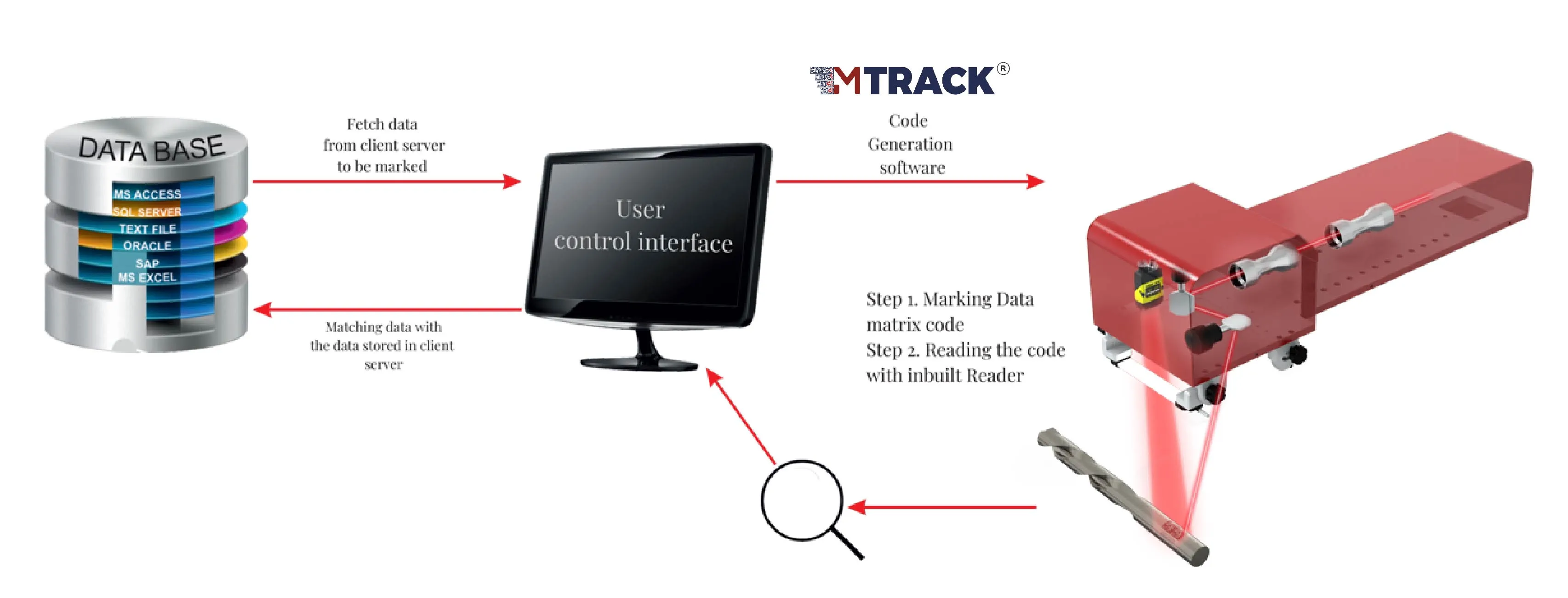

Tools Traceability

We do not "Reinvent the wheel" , we use the best technologies from

The identification code contains the supplier details, date of manufacture, and warranty details that imply that the tools are of premium quality. The identification code creates a trust that the tools are genuine and are supplied by a genuine supplier. The long DPM code (data matrix code ) is preferred in the industry because that can contain as many details and history. It also helps in recording the in-process data, i.e, the tool used for the operations, when and by which operator it was used, and it helps identify child parent relationship between the tools for the application.

Unique Code on Tools Helps Simplify Inventory Management

The unique code on the tools gives a record of identification of how many tools are present in the inventory, how many tools are missing, which tools are generally used, which tool is missing, what all tools break down and go through a lot of wear and tear. In the high production environment, the tools break a lot. Therefore, if the tools are not present in the inventory, they may stop the complete production line. We mark the tool with utmost precision having a deep dark mark over it. The clean, legible marking on tools stays forever and can resist any difficult environmental condition.

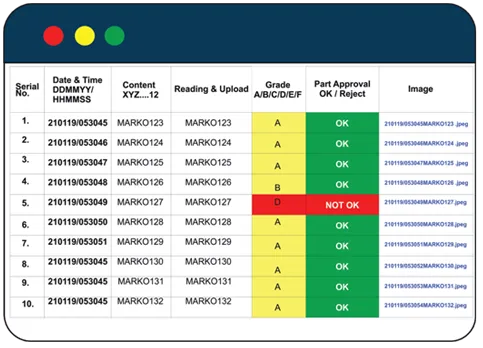

Production Log & Analytics

Markolaser Advantage

Production log helps in identifying the component and trace data, the grade of 2D data, rejected part in the production process and uploaded images of the 2D code. Built in analytical tools for quick tools for quick analysis

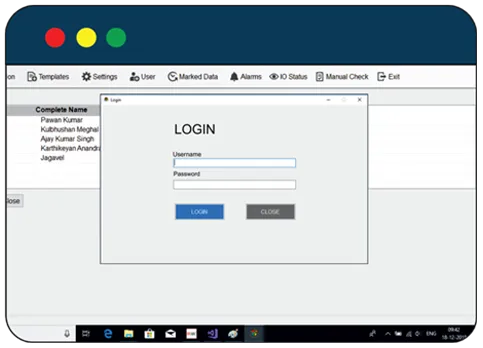

Administration Level

Various access levels can be set for operators. hods, plant head etc. Unique login can also be made for added security

Tools are repaired for reuse, they are sharpened and replaced with new ones. The tools monitoring software gives clear visibility of tools. It gives an analysis of tools present in the stock. The preventive measurement analysis helps the workstation and production move smoothly. Thanks to MTRACK solution and Markolaser's laser marker for traceability. This identification solution has made operators' life more manageable. In addition, automatic alerts and follow-ups make it easy for a user to recall what needs to be done.

Objective-: Easy Tool Identification

Database Integration

Code Generation & Marking

Inspection & Validation