Laser Traceability marking solutions: As the Manufacturing industries are expanding their businesses globally, there is a challenge to manage quality, liabilities, recalls, inefficiencies in manufacturing, counterfeiting, cost savings, tampering, building customer loyalty and much more.

To overcome these confrontations, more and more industries are focussing on compliances and quality regulatory mandates, leading to the need to trace a part’s origin through documented records and visibility across the manufacturing process. Traceability is the process that enables companies to trace goods backward along the supply chain and forward along the distribution chain, based on identification characteristics, which shows who, what, where and when things happened.

Actually, traceability is an insurance of the product that shows the authentication of manufacturing which acts like a risk management tool.

For effective traceability of parts in manufacturing, the companies have to shift towards automated capturing, storing and managing data that can be extracted in a single click giving real-time information about the product and equipment. Thus traceability processes ensure that the product quality standards are met to complete tracing and tracking of components in their entire life cycle by linking a unique identification (UID) to a database. The unique and unambiguous ID (IUID) is a machine-readable (vision) coded information that can be interpreted through the use of optical scanners or cameras.

Types of UIDs

- Data matrix codes

- Bar codes

This micro-marking of UID codes can be put on to the parts in the following different ways:

- Label printing

- Digital printing

- Direct part marking.

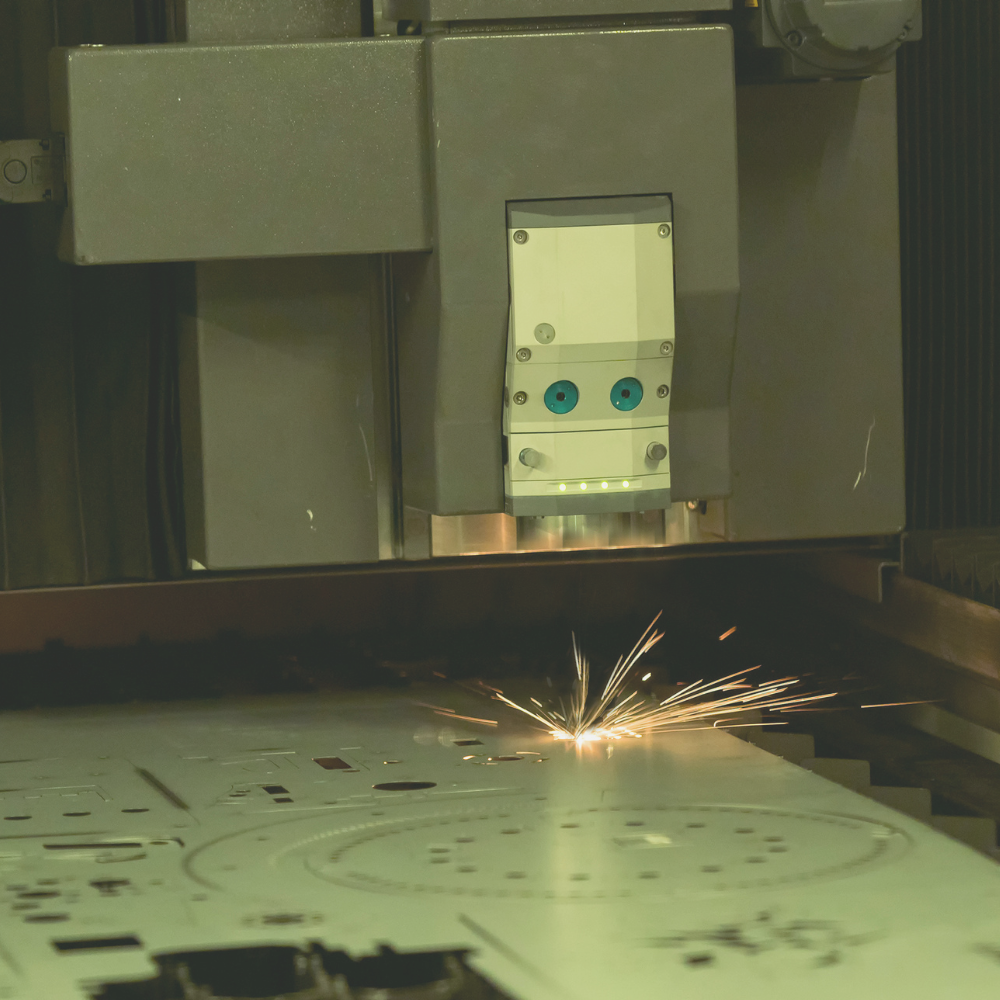

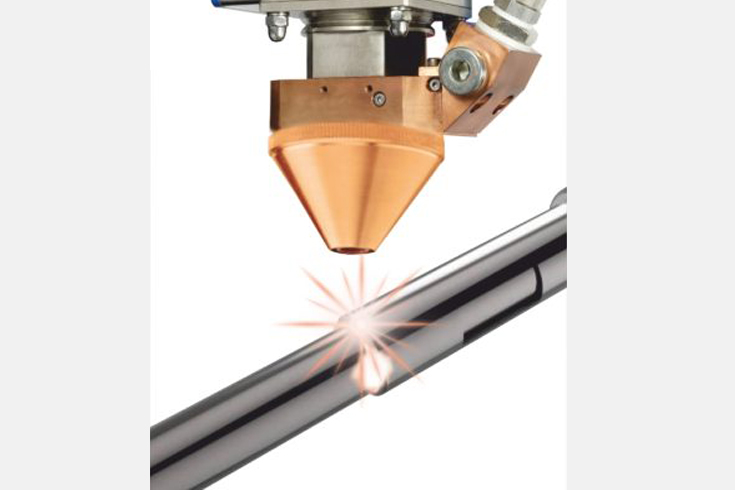

Unlike methods such as inkjet, dot peening, and electrochemical etching, direct part laser marking with MARKOLASER machines for traceability of parts, has several advantages, such as:

- Permanent marking, non-removable with any solvent.

- High contrast.

- High and fast productivity.

- No consumables or curing required.

- An economical solution because no pre-formed molds are needed for each code as it is needed in etching.

- Marking of smallest size machine-readable vision codes.

- Abrasion-resistant.

- Easily integrable with software and databases thus, automation-ready

- Flexibility to mark/engrave on difficult, thin and small areas.

The powerful combination of laser marking technology and machine-readable vision codes enables absolute product authentication, track, and trace. This is invaluable in the production process, distribution chain, and to end-users and consumers.

Direct part marking has become a necessity in many industries like food and beverages, medical, electronics, aerospace, automotive, tools, and dies and many others where safety is a bigger concern.

IOT ready traceability solution

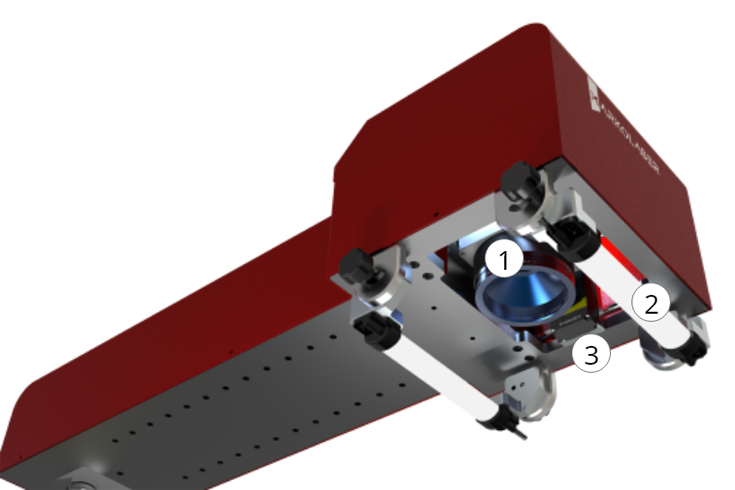

Exceptional Class 1, CE certified super precise machines, comparable to any best machine in the world, in this category, are made with the finest genuine components for unsurpassed precision, ideal for smart manufacturing in tool rooms. Smart manufacturing encompasses GMP (Good Manufacturing Practice) and IOT ready solutions.

These machines are highly compatible with industry 4.0 standards and can communicate to any database present in any corner of the world. These machines can communicate both ways to a cloud database. Thus, providing the real-time status of the operation to the Supervisor Control. Being IOT ready, these machines can provide a complete solution for any traceability requirement which is a must in today’s industrial scenario. Automobile and medical industries are adapting traceability very quickly and electrical & jewellery industries are the next in line to adopt traceability.

Traceability gives a huge scope for quality control to the industry as one can track the manufacturing date, batch, composition, opportunity on a part done by its supplier. This creates the possibility to overcome and monitor any performance-related issue and gives you the option to analyze its cause.

These machines are super controlled for expansion and contraction. So, we have a built-in European panel AC. High precision X-axis and rotary indexing system, which is based on feedback. This EXPORT oriented laser machine comes with optional special gantries, rotary systems & granite base.

Laser traceability marking solutions samples

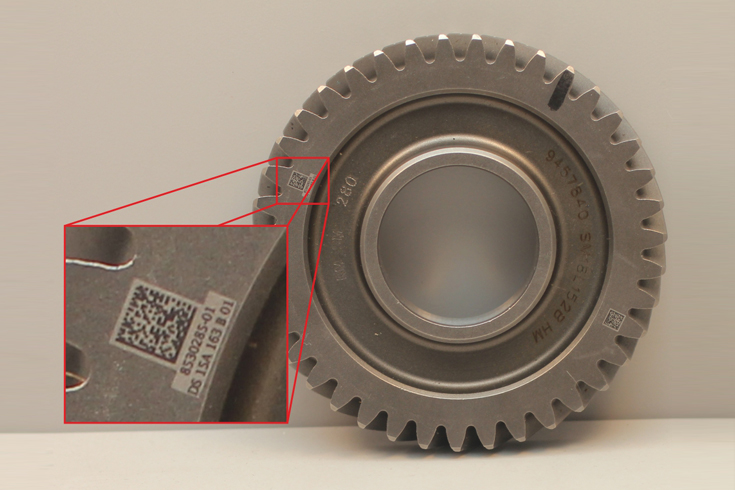

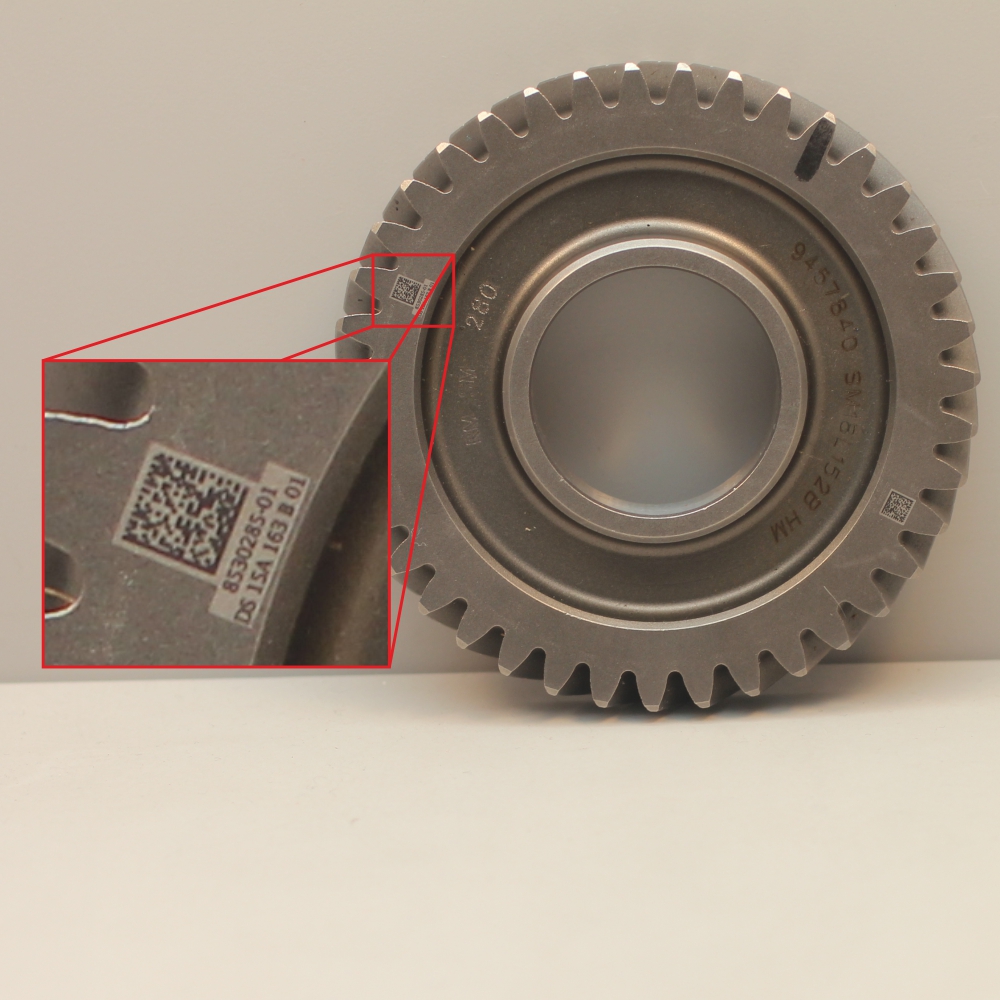

Gear traceability on metal

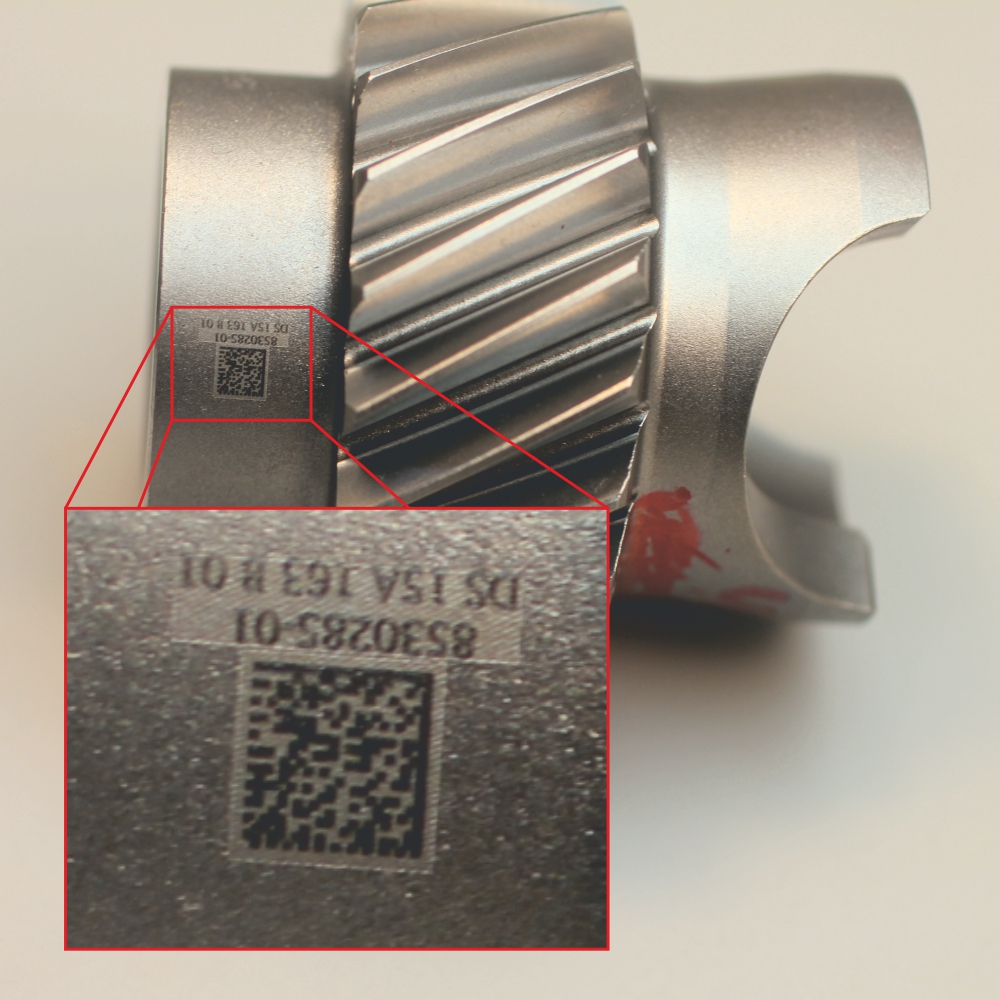

Gear assembly traceability on metal

Casted automotive part traceability on metal

Gear with teeth Traceability on metal

For more details visit us at

Email us:

info@markolaser.com

Check-out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For the jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |