- Have any questions?

- +91 9210626626

- info@markolaser.com

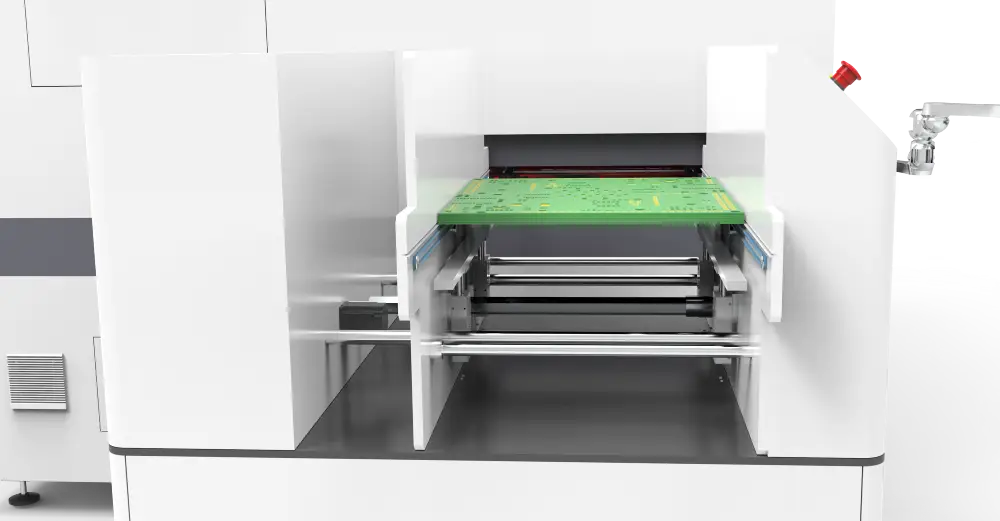

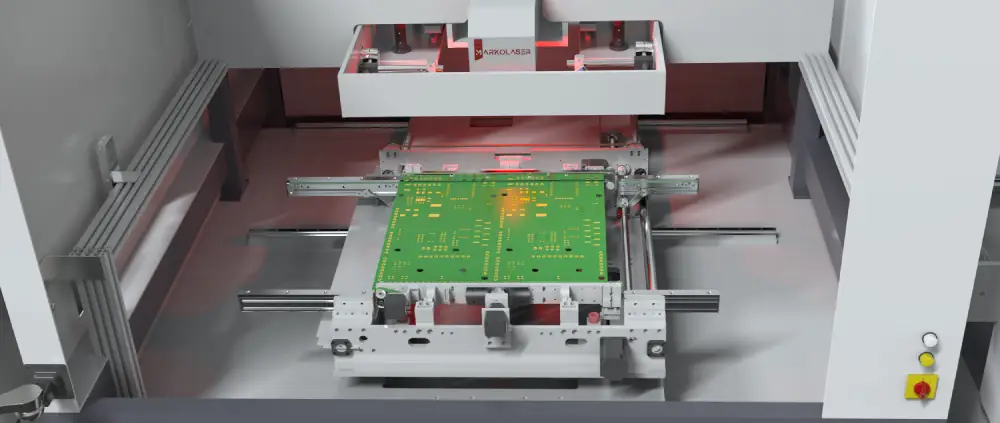

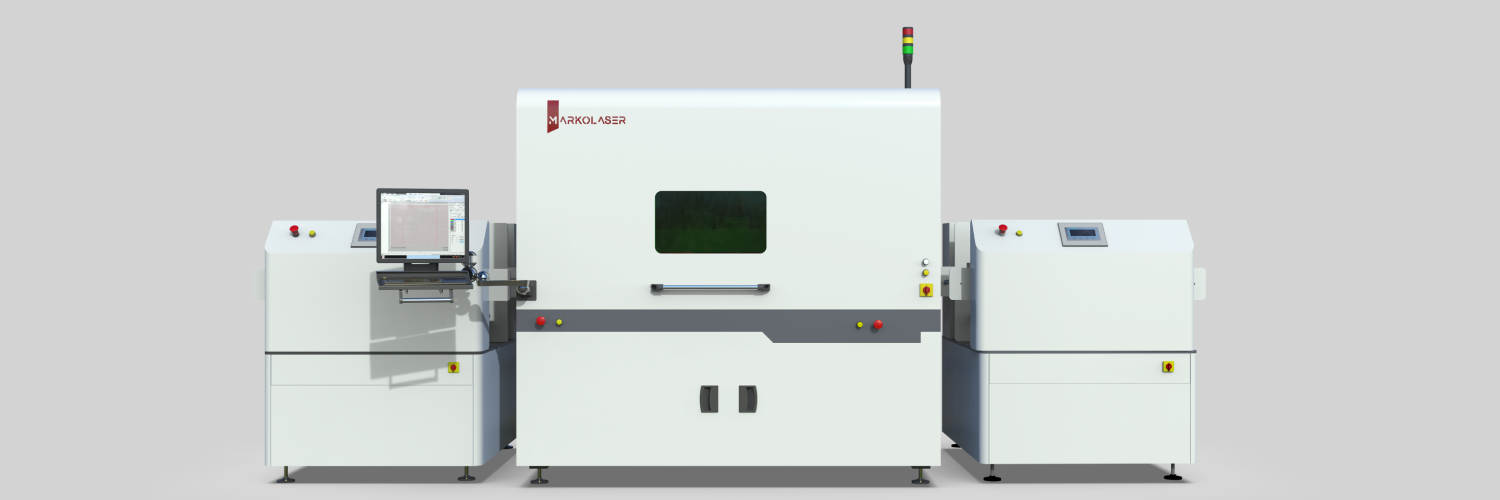

Automatic PCB Laser Marking Machine

Marking on PCBs must be done carefully, the need of the hour is to use the foremost Laser Marking Machines for PCBs. We at Markolaser provides optimal Automatic PCB Laser Marking Machines which can mark on both sides of the PCB. Have all the features which are useful for PCB marking. These machines are designed for marking 1D, 2D codes, QR codes, DM codes, barcodes, etc. The most important feature of this machine is that it can do Automatic track width adjustment to match up different production line. Appropriate to mark FR4 grade, resin (plastic), ceramic, paper, glass material. This machine also has an inbuilt scanner that is used for verification of the marked code. This newest marking machine equipment is meant for fruitful outcomes. Best option to use for printed circuit board marking.