- Have any questions?

- +91 9210626626

- info@markolaser.com

About Laser Sources

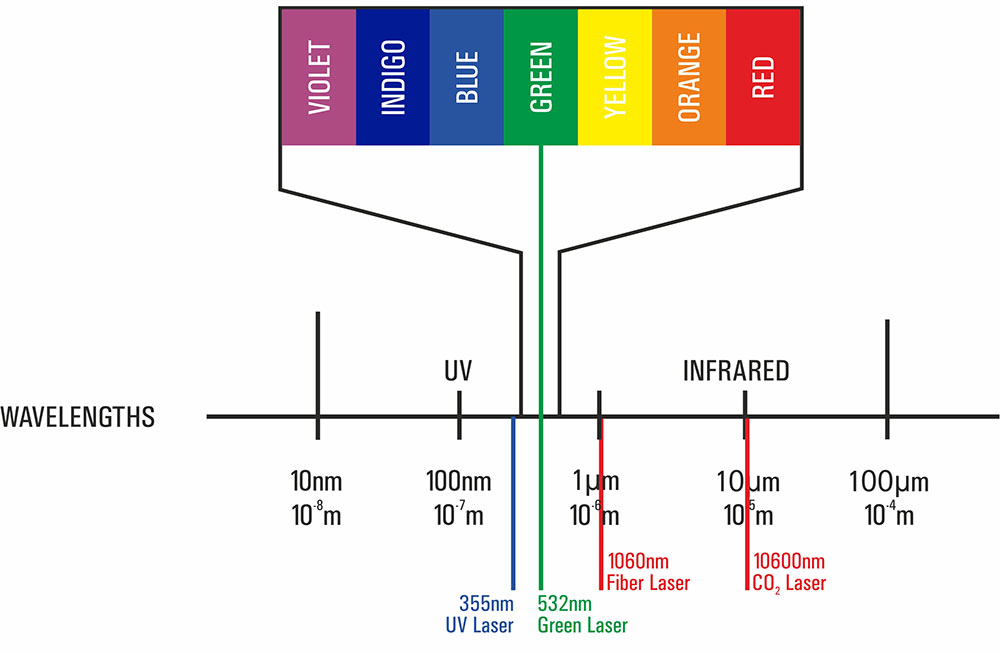

Fiber Laser

A Fiber laser utilize an optical fiber that is doped with rare-earth elements such as Erbium, Ytterbium, Neodymium, Thulium, and Holmium to produce beams of coherent light. We at Markolaser offer short pulsed lasers like picoseconds and femtoseconds for micro-machining applications. Read More..

CO2 Laser

Carbon dioxide lasers are one of the highest power continuous wave lasers. The high efficiency of carbon dioxide lasers leads to a power output that is approximately 20% of input pump power. And this infra red laser beam is what the CO2 Laser produces Read More..

Green Laser

A Green Laser has a 532 nm wavelength and falls under the visible (green) spectrum. One of the advantages of a green laser is that it is better absorbed by highly reflective materials. Read More..

U.V. laser

In U.V laser Ultraviolet lasers fall in the range of invisible light wavelengths of 150 to 400 nm. Ultraviolet lasers are classified as : Solid state Q-Switched, gas and metal vapour. Read More..

Before Selecting your Laser Machine, We need to know the 3W's

What to execute

Where to execute

When to execute

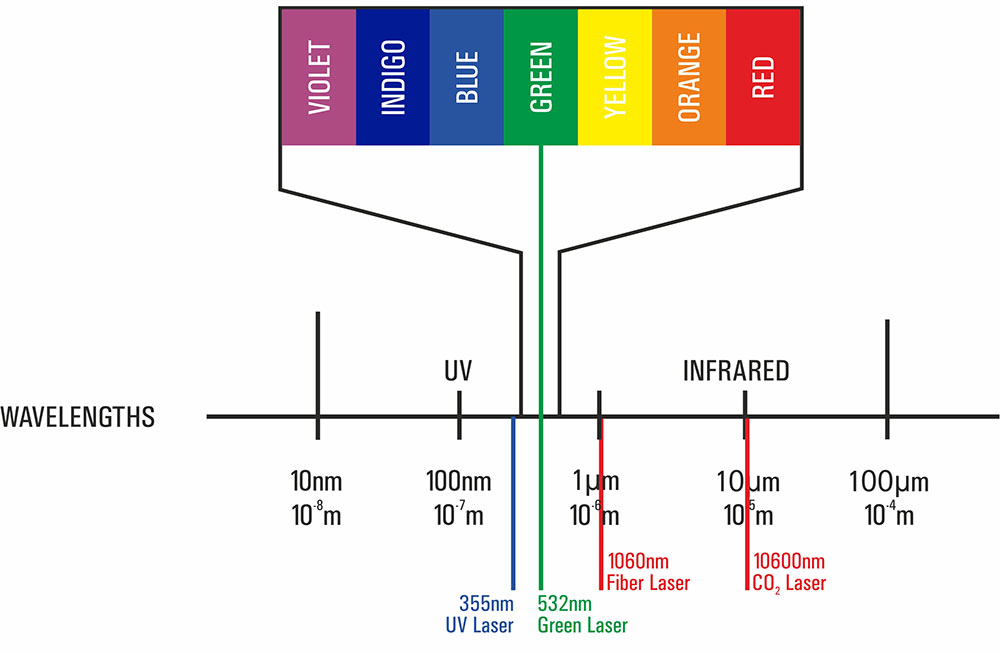

What to execute: Data can be collected from one source and used for the next instance. The data should be defined like a data set of text, image, or data of a predefined syntax such as an .ai,.dxf and others. The data/artwork file should be compatible to import to Markomark software

The source of data can be one for an instance and the other source can be used for the next instance. The data is to be defined such as a data set in the form of text, image, data set in a predefined syntax such as an .ai, .dxf and other. The data/artwork file should be compatible to import in Markomark software.

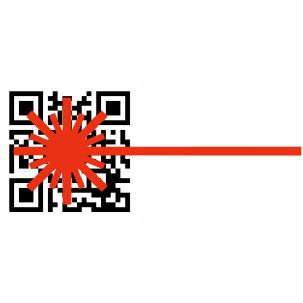

Where to execute: This defines the surface/object to be marked

The surface/object can be flat, cylindrical, or anything that you want; but we need to pre-define it so that the automation line is able to use it. We need some way to identify the surface/object in case there are multiple surfaces and objects. Alternatively, a QR or barcode could be used for identification purposes if that is easier. The surface needs to be taken somewhere for processing; this will probably involve either a pick and place mechanism or a conveyor belt.

When to execute: This defines the conditions for the event of marking

Again, there is only one exception to the 3W rule and that's the material. A piece of metal will respond best to a 1060nm Fiber Laser whereas Wood & Fabric type of material should be processed with a 10.6 micron CO2 laser. Glass can be processed with a 532nm Green Laser and most plastics should be marked with 355 nm UV Lasers. That's why we always recommend testing your materials against lasers before you purchase anything so you know exactly which machine is fit for your materials. We have all these lasers available at our application centre so feel free to send us your samples and specs for testing!

Read More