Laser marking machine for swiss watch industries

Practical laser marking for part genealogy and traceability is indispensable. Laser engravings for art and design purposes is very essential in the watch industry.

Now in industry more and more laser machines are being used for marking and engraving for part serialization, part numbering, labelling as well as data matrix code.

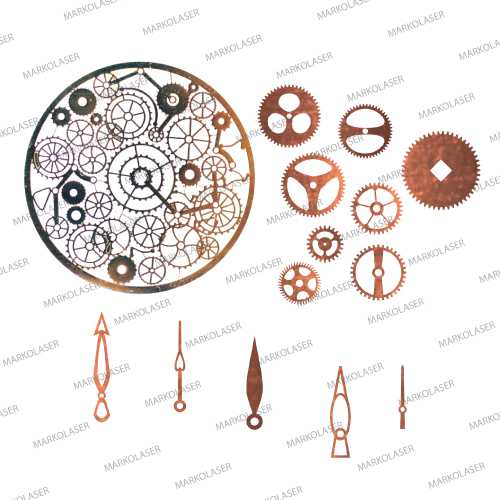

Decorative laser markings such as symbols, logos, icons and graphics, are applied to Swiss made watch parts. Clockwork components like minute and second hand , oscillation weights, bezels, crowns, housings, watch case backs or dials by means of laser marking, engraving & cutting.

The benefits of laser marking machine is that laser has highest degree of precision so that even the smallest of small art work and filigree laser cutting can be carried out with ease, efficiently, in very less time with a greater degree of precision.

What is the need of buying a laser marking, engraving, cutting machine for watch part?

Peerless and an unmatchable flexibility of laser machine

For laser marking, engraving & cutting

Laser system of Markolaser offers an unmatchable flexibility, allowing our partner to process on different material for all different applications, sizes, various wrist watch and clock parts, as well as the ability to produce one pieces or larger amount of parts.

The optional user control interface with IIOT enabled feature makes the system more transparent and accurate where feature like levels of authentication, report generation, alarm/event management, real time productivity report and management makes Markolaser unique and the Markomark laser software can quickly process variable and any amount of data according to individual orders with ease. Which result in less running time, minimum wastage and production. There is also an option for a camera assistant system (live view) integration that enables the user to see that laser marking is at right position or not.

Substrate on which laser engraving, laser marking & laser cutting can be done

- Titanium

- Ceramics

- Brass

- Stainless steel

- Gold silver, diamond & platinum other precious metals

- Leather (for the wristbands with wristwatches)

- Silicone , natural or synthetic polymer e.g. rubber

- Sapphire crystal

Benefits of laser technology with MARKOLASER

Dynamically the data can be processed, in this way it is the most flexible process

Any number and quantity of contents can be marked or engraved without the need of changing tools or refitting.

Smart and dynamic laser marking software Markomark, which can process the data with ease from the existing database, makes us unique Laser solution provider

Safe material processing with no contact with the material

The substrate doesn't need to be fixed or attached

It saves time and consistency lead to the finest result

Markolaser's broad product portfolio of Laser system gives a flexibility to choose the right machine for right application

Great accuracy is achieved with Scanner from SCANLAB Germany in one and first shot

Unlimited designing possibility

Any design can be realized with our laser system, Markolaser give full freedom to there clients

Even the font size of 0.1 mm or smaller geometries are still clearly legible with our laser marking machine

Markolaser gives full design flexibility while designing marking, logos, designs, art, data-matrix, bar codes or serial numbers

With Laser Software Markomark laser marking, engraving and cutting is carried out with ease.

Permanent impression

Laser marking results in permanent impression with abrasion-resistant, as well as heat and acid resistance mainly while marking bar-code, QR code and data-matrix code

Prototyping with Versatile applications are possible

Varieties of substrate such as acrylic, leather, metals, polymer can be processed with a laser system