Laser Engraving Machine for Dies and Moulds

3-Axis free form laser engraving and inscription machines for 2D / 3D engraving on filigree cavities, forming dies, forming tools, embossing tools, mold inserts, extrusion dies, 3D laser texturing injection molds.

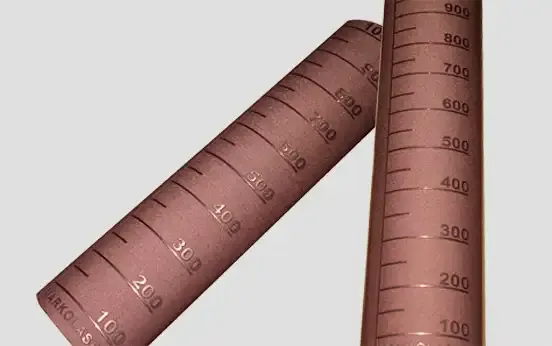

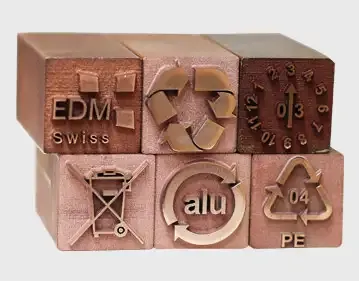

Electrode Construction

3-Axis laser engraving on a curved copper EDM electrode. Speed up electrode manufacturing with laser systems manufacturing of electrodes is an essential step in the development and construction process of a tool which require electrical discharge machining (EDM) laser engraving machine helps in accelerating the production of electrodes of any complexity. (this is not clear) With the help of an advanced 3-axis laser cutting or engraving machine, electrodes can be made, ensuring that they are finished with smoothness and accuracy .Our step-by-step solution lets you automate the entire process from design through production – thusreducing time and production costs.

URSA ( 3-axis laser system)

Hercules

3D Laser Texturing

Fiber Laser

Engraving on Hardened (hrc 60 – 62) Cold Working Steel for Punching

Cold working hardened steel (HRC 60 - 62) can be engraved for punching die making based on its application and requirements. In order to choose the appropriate steel for a die, it is imperative to be aware of tool stress which aids in determining which grade of steel should be used. The best way to make punch dies is by laser engraving and cutting. The tools used to make punches may break due to their differing hardnesses

Laser Engraving on

Coin Die

Extremely fine engraving on steel punches used as embossing tools for hallmarking on jewellery and by the swiss watch industry as ‘case makers mark: Poinçonsde Maître’. They are specially curated laser engraving systems with extremely fine laser beam diameter < 20 um. Our specially curated laser engraving machines are used for such fine and intricate work.

Orion- Less is more

URSA- Jack of all trades

Jewellery (hallmarking)

Watch industry

3D Laser Surface Mold Mould Texturing Machine- Plastic Injection Molding Laser Micro Milling Machine Manufacturer

3D deep laser engraving of a plastic injection mold of a mobile phone cover.

Our 3-Axis laser engraving and texturing machines

URSA- Jack of all trades

Hercules

3D Laser texturing

Laser Applications

Application of Logos, Inscriptions and Engravings, Even in 3D

Tool/mould construction

Coins/medals

Electrode production

Filigree Cavities in Miniature Technical Forms,

e.g. for:

Tool/mould construction

Toy industry

Electronics

Lifestyle

The Finest 3D Contours for Tool and Mould

Construction in:

Compression moulds

Forming dies

Forming tools

Inserts

SS Metal Die Engraving Applications

3-Axis 3D Laser Texture Etching of Injection Molding Die on a 3D Dimensional Freeform Surface.

- 3D laser surface texturing for plastic injection molding

- Our 3-Axis laser engraving and texturing machines

- URSA- Jack of all trades

- Hercules

- 3D Laser texturing

3D Laser Surface Mold Mould Texturing Machine- Plastic Injection Molding Laser Licro Milling Machine Manufacturer

3D deep laser engraving of laser wood texture on a plastic injection mold of a mobile phone cover

- 3D laser surface texturing for plastic injection molding

- Our 3-Axis laser engraving and texturing machines

- URSA- Jack of all trades

- Hercules

- 3D Laser texturing

SS Metal Die Engraving Applications

Embossing and engraving of fine 3D designs and textures on hardened cold working steel with hardness ~ 60 – 62 HRC. The hardened hammers are used to give ornaments textures. Popularly used by jewellers and designers to produce unique textures and designs.