Laser Cleaning

Laser cleaning is the contact and wear free, eco-friendly and selective removal of unwanted contaminants like rust, debris, dust, carbon black, silicone, rubber, vulcanization residues or oils and fat which develop as process residues during manufacturing. Laser cleaning is also done for paint removal, surface profiling, rust removal in steel fabrication, de-coating, mold cleaning, de-oiling, activation, restoration, special surface treatment and even labelling and marking. Laser ablation is the essence of laser cleaning process.

It can be applied on glass, ceramics, metals, concrete, plastics, injection molds, cast parts for removing paint from metal and polychrome surfaces, stripping insulations from conductors and de coating paint from delicate surfaces with minimal impact on the base material . Other important applications of laser cleaning is art restoration.

Industries like automotive, steel fabrication, aviation, art recovery and high value manufacturing prefer laser cleaning method for surface cleaning.

-

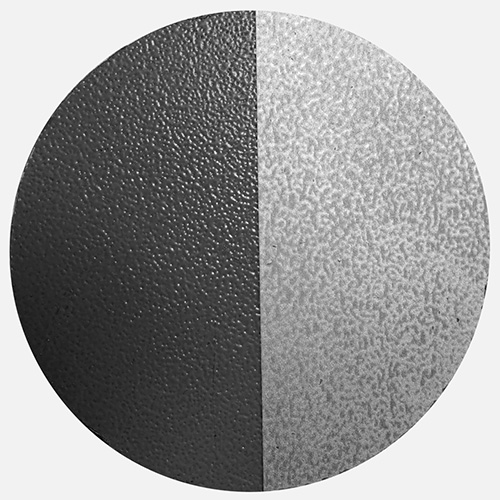

Laser cleaning on metal

Features:

-

Object name: Coin

For sampling and machine related queries for above shown applications please mail us at: info@markolaser.com -