Laser engraving on metals is widespread and is essential for all OEMs and Industries who are manufacturing products.

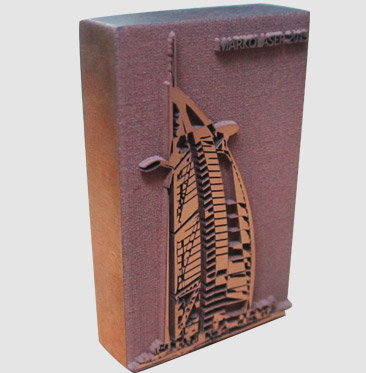

These engraver are useful in creating brand value by creating design and logo over the surface of metals

Metal laser engravers are useful for various applications such as laser deep marking, laser texturing, serialization, permanent laser branding , DPM on automotive metal products/parts and UDI on non corrosive surgical equipment and implants.

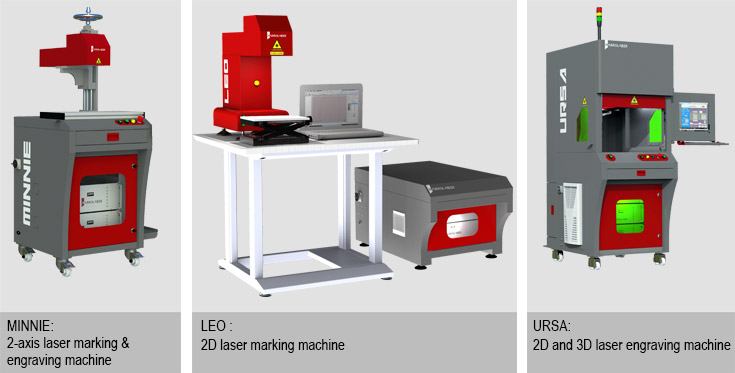

Markolaser designs special SPM for engraving on metals. Metal products are very heavy and difficult to handle in an industrial environment. Need special fixtures and robots with the synchronization of laser engraving machines.

What is Laser?

Laser stands for light amplification by stimulated emission of radiation. The laser produces a light that is functional for various technologies. A bright and narrow beam of radiation is generated by a laser. Light by a laser is monochromatic and concentrated in a precise direction. Laser is a flexible technology that is used for a variety of applications such as cutting, welding, marking, engraving, and others. Laser technology is a growing technique, it is used in various industrial and commercial operations. Laser systems use divergent lasers and systems to do engraving or marking in a systematic way.

About Laser Engraving

Laser engraving is a marvelous process in the 21st century. The method in which there is the use of a laser to engrave a design on metal, jewelery, glass, wood, and others. In simple terms, we can say creating deep marks on a material with the help of a laser. Laser engraving offers great results with multiple benefits.

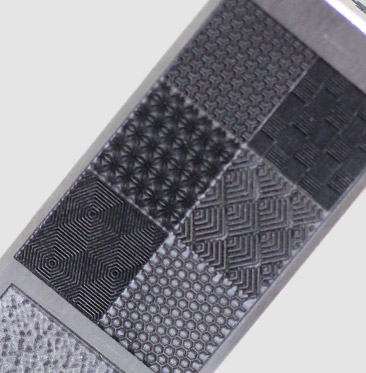

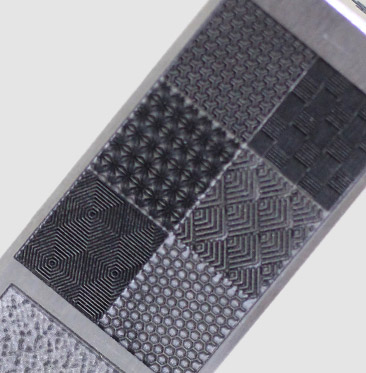

Laser engraving is a kind of art that is performed on different shapes. The surface on which marking, designing, and engraving take place results in excellent finishing.

Conventional techniques for marking or engraving on metals or plastics are now replaced with the help of splendid laser marking machines. The process followed by this machine is successful due to its high speed, fast results, and outstanding working technique.

High-powered lasers are used to heat the material, therefore removing material and creating marks as per the requirement. The present world is now focusing on permanent marking solutions using a beam of light. The notable point in this process is that doesn’t require inks. That’s why people in this modern world are learning about this process and finding out how this method will help their business. The laser engraving technique is mainly used for product identification and offers fruitful results to businesses across the globe.

A beam of light plays the foremost role in the entire process of laser engraving as without it we can’t do engraving. Engraving technology is used for various industries such as automotive, medical, jewellery, educational, and various others. If you want a smooth and long-lasting marking solution, then you must go for laser engraving. The outcome of this method is completely human readable and ameliorate the product.

This great technology can be applied to engrave text, logos, barcodes, serial numbers, and other information on various surfaces. Laser engraving is now easy after the introduction of the laser engraving machine. Let us now learn about this machine.

About Laser Engraving Machine

Laser Engraving Machine uses laser technology to do marking on various surfaces. It is made up of the best materials. There is a need for a beam of light, a controller which is responsible for speed and movement plus it also determines whether the laser beam falls on the required surface or not and the most important is the surface on which we need to do engraving. Numerous laser engraving frameworks are available as per the area required for engraving and other technical specifications.

Fiber laser engraving or marking machines are the most preferred among customers as these machines require low maintenance costs. Result by these Frameworks is fast and accurate.

Industries that need to engrave data like expiry date, manufacturing date, batch number, and other useful information in neat and readable form are using these machines and are getting numerous advantages in an easier way.

Difference Between Laser Marking and Laser Engraving

| Laser marking utilizes a low-powered beam of light on a surface of the material by changing the material appearance resulting in producing superior marks on the surface. | Laser engraving utilizes a high-powered beam of light by removing the material from the surface which needs to be marked and results in producing premium marks on the surface. |

Laser Engraving on Metals

Laser engraving on metals like aluminium, copper, titanium, and brass is possible due to laser engravers. The working principle of these engravers is exemplary. This laser engraving machine is in tremendous demand these days because many industries such as automotive, electronics, and various other industries want to present their brand in front of customers.

Not only for branding, but laser engraving can also be used to engrave data matrix codes, barcodes, and numbers on various metal surfaces. These latest engraving machines are fully capable of doing their jobs with unique features therefore, we get flawless results with this technology.

Laser Engraving on Aluminium

Aluminium which is also called as aluminum. The appearance of this metal ranges from silvery white to dull gray. The density of aluminium is lower than that of other metals. It’s symbol is Al with the atomic number 13. It has high thermal conductivity. It is used in industries such as automobile, aircraft, aerospace, packaging, construction, and various others.

Laser engraving machine or marking machine for metal is used by many industries. As discussed above, laser marking is a permanent solution and this mark will not come out after washing or if we try to remove using our own hands.

Our magnificent engraving machine for metal such as aluminium provides a high-quality marking in a sport span of time. With our machines, one can do deep engraving on the surface of aluminium.

Superior metal engraving machines for utilized for aluminium engraving. These are of two types known as Fiber laser machines and CO2 laser machines. These laser marking machines are controlled using laser software. You can mark QR code, serial number, or other data.

Copper Laser Engraver

Copper has pinkish-orange color. The symbol of the copper is Cu and it’s atomic number is 29. It is malleable and ductile and has various applications. It is also available in different foods and potable water. It is important for human health. Copper density is 8.96 g/cm3. It can be used in the medical industry, jewellery industry (alloys are used), musical industry (for instruments),and others.

We provide the best metal laser engraver for copper. Fiber lasers and UV lasers are available with us for marking or engraving on metal known as copper. It’s not difficult to mark on copper with our amazing machines. Markolaser is not only involved in providing marking or engraving solutions but it is also called as the brand which provides great laser solutions under one roof.

For example – If you want to do laser engraving or marking on bottles & utensils made up of copper then you need to know about this engraving machine. Engraving on Copper electrode and dies are some of the well known application of engraving on metals

Some parts of the musical instruments are made with copper, creating brand logo and brand design gives the instruments a better look and feel.

Nameplate and housing of electrical instruments are made up of copper and technical specifications engraving on those products is must. The metal laser engraver is a blessing and typically the best solution for copper user and their applications.

Engraving on Stainless Steel

It is an iron and chromium alloy. It is useful in many industries. It contains at least 11% chromium and also other common alloys. These alloys are nickel, nitrogen,and others. High resistance to corrosion, high strength, and low maintenance are some of its properties.

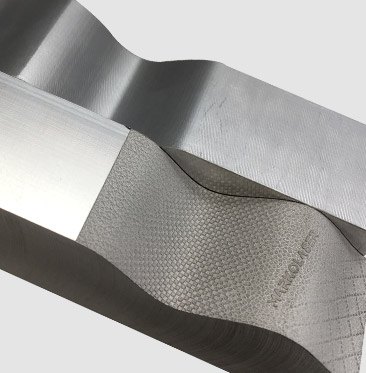

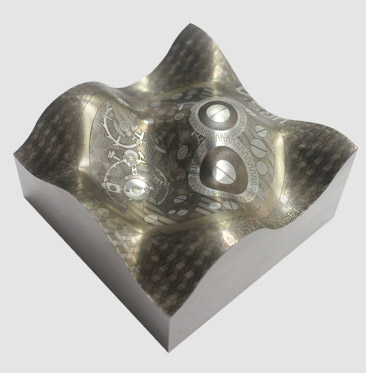

For laser engraving or marking, an excellent metal laser engraver is used which is fully capable to perform its work. We have 3D laser engraving machines that can do deep engraving on stainless steel.

For example, if we want to do marking(texturing) on a steel plate or on a spoon made up of steel then get the metal laser engraver from the house of Markolaser gives an amazing results as per your need related to marking or engraving text on a steel plate or any other thing which is of steel.

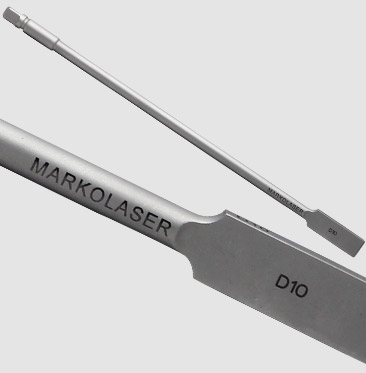

Stainless steel is the preferred metal in the medical industry, All the surgical instruments are made up of special types of SS that are non corrosive. Laser Marking which is also termed as UDI marking is a must to trace the history of that surgical instrument. The history could be the date and time of usage, the patient on which the instrument is used and the test that it has gone through.

SS is useful in hydraulic, chillier, piping industries. Branding, serialization, electrical & mechanical Specification engraving are some typical applications of lasers.

DPM on automotive parts such as automotive gear assembly, automotive housing, bearing and gears is a well known application. We create specialized automation with robotic integration to fit our laser engraver to the OEMs manufacturing lines.

Die manufacturing for precise work needs SS of hardness (HRC 63). Laser engraving for manufacturing these precise dies helps the die maker grow their business. Precise dies create beautiful accurate output.

Laser Marking Titanium

Titanium is a silvery-gray metal with the symbol (Ti) and atomic number 22. It is a shiny and non-toxic metal. It is used in various industries such as medical, power, and gas. Titanium as titanium oxide is used as a pigment to color paints, plastics, cosmetics, milk etc.

Conventional methods used for laser marking on titanium are now replaced by new technology which has various advantages. Our powerful laser frameworks with a combination of latest tools and technologies can remove hard metals and create perfect markings on metals such as titanium. Which system is perfect for your application completely depends on your requirement.

For example, we want laser marking to be done on a clasp locker which sounds really interesting. The locker by which we are able to open or close it needs to be marked. The titanium laser marking machine is available with us to proffer high-quality results.

Laser marking on titanium surgical implants for traceability is an essential requirement of the medical industry.

The original equipment/surgical equipment/implants/stent manufacturer needs UDI code over the metals.

These UDI marking needs to be corrosive resistant and passivation resistant.

Thanks to Markolaser Solution’s UDI marker/engraver integrated with MEDITRACK traceability. Our MEDITRACK medical traceability software records the supplier details, details of a patient on which these titanium tools are used, and the stent; implant which are present inside the human body.

Hallmarking & Engraving on Silver

Silver is shiny metal and it’s symbol is Ag. It is a valuable metal. It’s atomic number is 47. It has high electrical conductivity. Silver nanoparticles are utilized in the clothing industry. It is used in coins, jewelry, utensils, engine bearings, and solar panels etc.

Laser printing on metal surface or on silver is possible because of recent updates in technology. These new and advanced engravers work in a great way.

Fiber laser engravers for metal are the best suited to engrave a design on silver coins or any other sliver pendant. We have the best laser engraver that proffer’s beautiful designs. The complete laser engraving process is controlled by a digital system.

Laser Hallmarking on silver jewelry is one of the important requirement that every jewelry maker needs.

Hallmarker for Gold

Gold is a precious metal. It’s atomic number is 79 and the symbol is Au. It is of yellow color and is a very useful and expensive metal. It is used in the jewelry industry, electronics industry, medical industry, food and beverage industry, and others. Most of the gold is used in making jewelry as women love to wear necklaces, rings and bracelets made from gold.

Gold items such as pendants, rings, earrings, and others become more valuable when there is a beautiful design on the jewelry you wear. This delicate metal needs special attention therefore decoration or text engraving on gold products is done by choosing the right method. We have the appropriate machine for engraving on jewelry. Our laser engravers are doing a great job in the jewelry industry. Laser engraved gold markings are of high quality and 100% accurate.

Not only for decoration purposes but laser machines are also used for jewelry cutting. We have excellent laser cutters which can cut different pieces of jewelry and provide high-accuracy solutions and opportunities for the designers to create different shapes on a piece of jewelry.

Fine cutting/engraving on a gold bangle is possible with World’s best laser systems to create an attractive piece of jewelry after the laser cutting process gets over. Our laser systems are well-suited for cutting/engraving precious gold ornaments.