We are excited to share with you the latest advancements in laser technology and the innovative solutions that Markolaser offers to meet the demands of the modern world.

With traditional laser processes no longer sufficient for many clients’ needs, Markolaser’s state-of-the-art laser systems provide highlighted features that are unrivaled in the industry. Our machines are designed with the highest quality components very carefully sourced from Europe and are user-friendly, ensuring maximum efficiency and productivity.

At Markolaser, we understand that each client has specific requirements. Therefore, we offer customized laser machines that can be tailored to meet your unique needs. Our commitment to customer satisfaction extends beyond the initial sale, as we provide excellent maintenance services to ensure that your machine runs trouble-free for years to come.

Investing in industrial laser machines is crucial in today’s market, and Markolaser offers various specifications to meet your specific needs. We believe that our cutting-edge technology and unparalleled customer service make us the ideal partner for your laser processing needs.

Industries where laser machines are used

- Medical

- Label

- Jewelry

- Automotive

- Educational

- Watch

- Tools

- Electrical & Electronics

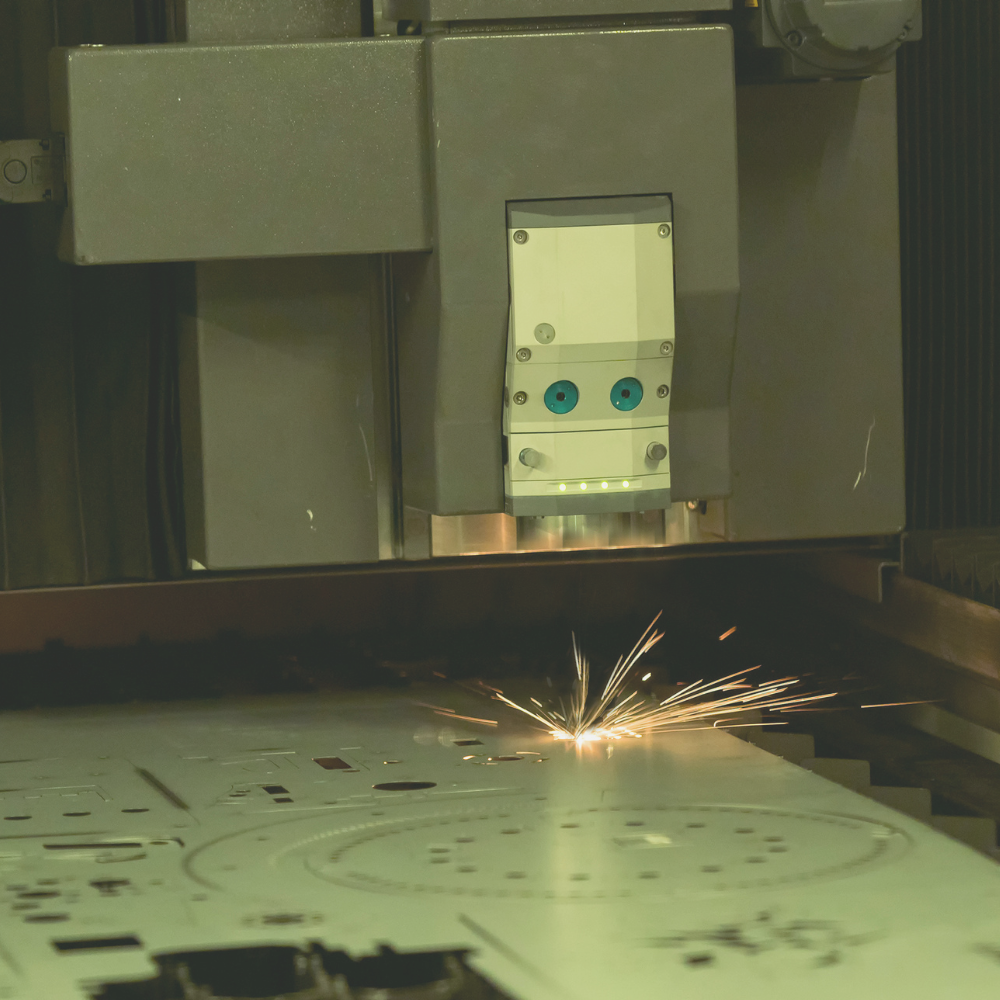

Laser welding technology is an impressive innovation that has revolutionized the welding industry. This process involves the use of a laser beam to weld metals or thermoplastics, producing extremely precise, narrow, deep, and high-quality welds. One of the main advantages of laser welding is its non-contact nature, which eliminates the need for any physical contact with the workpiece during the welding process.

This technology is incredibly versatile and can be used on a variety of materials, including stainless steel, titanium, and aluminum. It is capable of producing welds with exceptional accuracy, strength, and reliability. Additionally, laser welding is a very clean process, as it does not produce any harmful fumes or by-products.

The laser welding process operates in two modes: conduction welding and keyhole welding. Conduction welding involves heating the surface of the material to be welded, causing it to melt and join together. Keyhole welding, on the other hand, involves creating a narrow, deep hole in the material, which is then filled with molten metal to form a strong bond.

The precision and speed of laser welding make it an ideal choice for many industries, including aerospace, automotive, and electronics. Its ability to produce high-quality welds quickly and efficiently has made it an essential tool for businesses looking to improve their manufacturing processes and increase productivity.

In conclusion, laser welding technology has transformed the welding industry with its precision, speed, and versatility. Its ability to produce high-quality welds on a variety of materials has made it an essential technology for many industries. As this technology continues to evolve, we can expect even more impressive advancements in the future.

Benefits of Laser Welding

- Fast technique

- High efficiency

- High-quality welds

- Precise welding

- Ability to weld dissimilar materials

- Lower heat affected zone

- Contactless process

- Enhanced productivity

- Versatility

- No electrode is utilized in this method

- Manufactured with excellent components

Types of Lasers

Solid-State Lasers – These lasers have high power. Here, the active medium is solid and can be glass or crystalline material. Solid-State lasers have high efficiency. Their construction is simple, and output is in the form of continuous or pulsed. They are used for drilling, welding, etc.

Liquid Lasers – In these lasers, the active medium is liquid. They are also called dye lasers. In liquid lasers, the active material utilized is called dye. These dye lasers are utilized in medical applications as research tools. Have less beam diameter and splendid beam quality.

Gas Lasers – Their gain medium is made up of one or more gases. It is a laser where an electric current is released through a gas to produce laser light with a process called population inversion. Some examples of gas lasers include CO2 lasers, argon lasers, krypton lasers, etc. They are used in barcode scanning, laser welding, laser surgery, etc. CO2 lasers are mostly used for laser welding, marking, and cutting.

Fiber Lasers – In fiber lasers, the active medium is an optical fiber. They are a type of solid-state lasers. These lasers have pre-eminent beam quality. Easy to install. They are utilized in laser welding, cleaning, marking, etc.

Semiconductor lasers – These lasers are small in size and also called as laser diodes. They work similar to LED but aspects of the output beam are of the laser light. Use low power and have many applications due to its size.

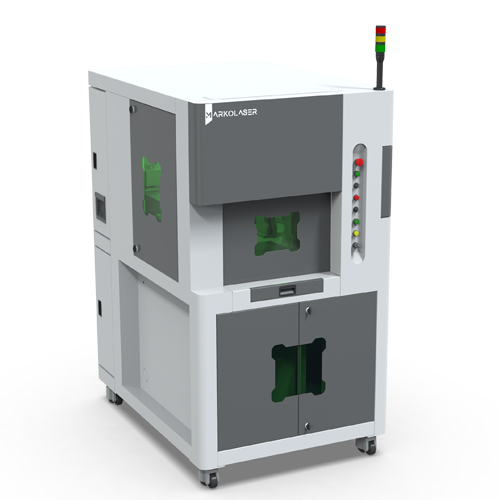

Laser Welding Machines

Markolaser is a leading provider of high-quality laser marking, engraving, cutting, and welding machines. Our laser welding machines are designed and manufactured to deliver precise outcomes with the greatest operational efficiency. Our machines are used in a wide range of industries, including automotive, medical, electrical and electronics, dies and tools, jewelry, and more.

Our laser welding machines (Markoweld) are highly versatile and can be used for different shapes and sizes, providing flexible welding results. They are reliable, flexible, extremely powerful, and advanced systems that have been tested on necessary parameters to ensure premium quality performance. Our welding frameworks have a long life and are appreciated by clients for their exceptional performance.

Markoweld offer numerous advantages, such as accuracy, precision, speed, and versatility, making them an excellent choice for welding by laser technology. Our machines are easy to use and offer accurate welding results, making them a popular choice for welding applications.

In summary, Markolaser’s laser welding machines are unique, reliable, and advanced systems that provide precise outcomes with high efficiency. With their numerous advantages, they are now the prominent machines for laser welding in various industries.

Automations & integrations

At Markolaser, we offer cutting-edge automation technology designed to improve manufacturing operations. Our fully and semi-automatic solutions are built to the highest standards and are tailored to meet the unique needs of each customer.

Our team of experts is always available to provide comprehensive training, service, and support to ensure the smooth operation of our automation systems. We understand that uptime is crucial, and our team is committed to minimizing downtime and ensuring maximum productivity for our clients.

One of our core technologies is our DPM (Direct Part Marking) system, which enables precise marking on automotive parts. This technology ensures that parts are properly identified and tracked throughout the manufacturing process, improving traceability and quality control. Our data management system also enables accurate measurement of productivity and per-day production, providing our customers with valuable insights into their manufacturing processes.

At Markolaser, we are well-renowned for our automation building, which is widely accepted in the industry for its quality and reliability. Our standalone machines can also be easily integrated into existing systems, making it easy for our customers to upgrade their operations and achieve maximum efficiency.

If you require further details on our laser welder, laser welding machine prices, jewelry laser welder, laser welding system, metal laser welding machine, or laser welding machine in Gurgaon, Delhi, Mumbai, Kolkata, Chennai, Agra, Lucknow, Thane, Bangalore, Bengaluru, Jaipur, Hyderabad, Surat, Ahmedabad, Chandigarh, please don’t hesitate to contact us at info@markolaser.com.

We would be happy to provide you with all the information you need to make an informed decision.

At Markolaser, we are committed to providing the highest quality automation solutions and exceptional customer service. Contact us today to see how we can help take your manufacturing operations to the next level.

Author : Dr Reetuparna Ghosh