Laser Cutting Process

Laser cutting is a process of cutting a material thoroughly with the use of a laser beam. As laser beam falls on a material it is absorbed by the material and heats up and evaporates the material. Laser cutting is a highly precise and accurateprocess that involves a focused beam to cut a wide range of material. Cutting by laser can be used for small and fine material (such as filigree) as well as on thicker material (such as metal sheets).

Materials that can be laser cut

Laser cutting is used to cut a wide range of materials such as stainless steel, Aluminum, Brass, Copper, Tungsten, Titanium, ceramics, silicon etc.

Applications of laser cutting

Laser cutting has a wide range of application in many small to big manufacturing industries. Listed below are some of the critical and important application of laser cutting:

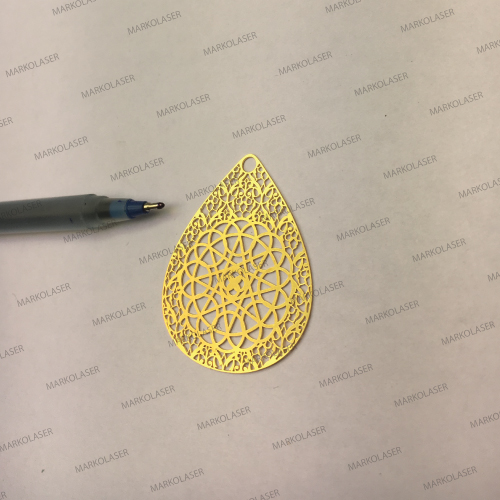

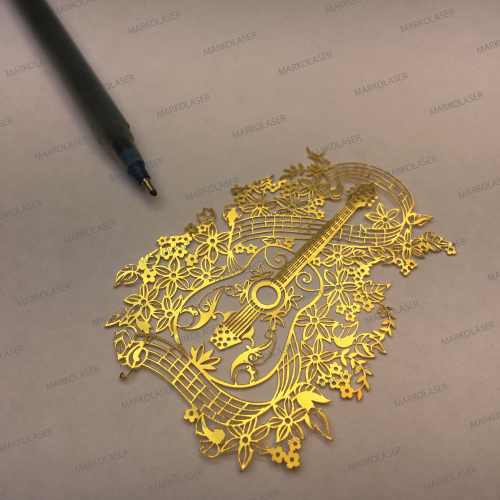

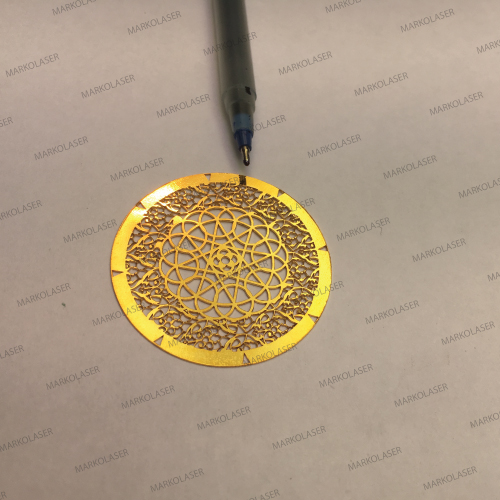

- Jewelry Industry has really gained the benefits of highly precise and accuratelaser cutting. Many creative, detailed and intricate jewelry designs are possible with preciselaser cutting technology.

- Laser cutting silicon wafers for solar cells

- Laser cutting stents in medical industry

- Laser cutting of thin foil (includes lithium battery foil)

Some key features of our laser cutting application:

- Laser cutting is a highly accurate & precise process.

- Laser cutting produces less HAZ (heat affected zone) that does not distort the material.

- Laser beam has high-energy intensity that overall consumes less power than conventional cutting techniques.

- Laser cutting is a contact less process.

Check out the laser cutting machine

Samples:

Visit our website at

Check out our website for different technologies

| For Inks printing requirement | http://www.spinksworld.com/ |

| For Laser printing requirement | https://www.markolaser.com/ |

| For Pad Printing requirement | http://www.padprintingpadsonline.com/ |

| For Digital printing requirement | http://kolorobia.com/ |

| For screen and pad printing | http://spinksindia.com/ |

| For jewelry industry | http://jewelaser.com/ |

| For coating and automation | http://www.spinkssoftech.com/ |