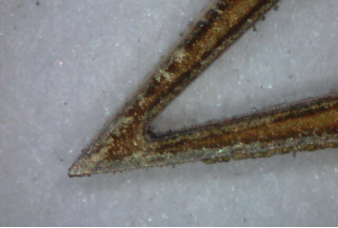

A comparative study was done by cutting fine samples of watch needles on a sheet of brass of thickness 1.2 mm using 20W and 50W fine fiber lasers. The primary reason behind this study was to determine the effectiveness and unparalleled results of fine sample cutting and hence the effects upon post-processing. Two fiber lasers (20W fine and 50W fine) are used to cut the desired shape using cold fiber laser cutting at a pulse duration of around 9- 13 ns. The comparative results show the differences in cutting of the samples before and after processing of the cut samples.

Listed below are some of the images showing the variation in consistency and post cutting effects of both the samples before processing.

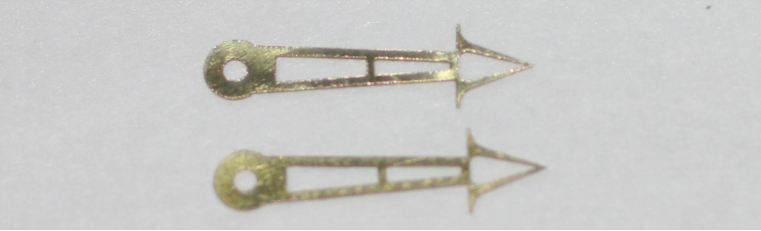

Tip of the watch needle cut by using 11 ns, 50W fine laser.

- Burring of samples is prominent, heat affected zone is more definite.

- Lesser sharpness. Imperfect material removal and more burning.

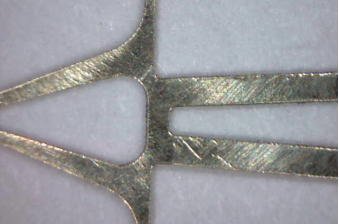

Tip of the watch needle cut by using 9ns, 20W fine laser.

- Limited burring of samples, heat affected zone and formation of metal bubbles on the surface.

- Better sharpness and lesser astigmatism. Better material removal and lesser burning.

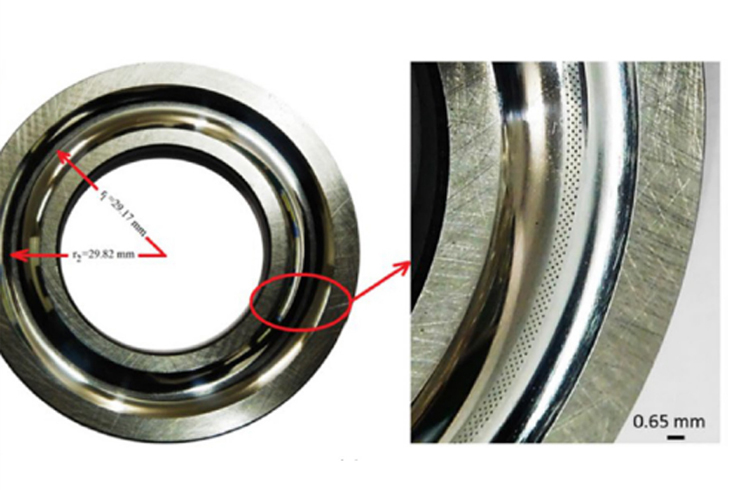

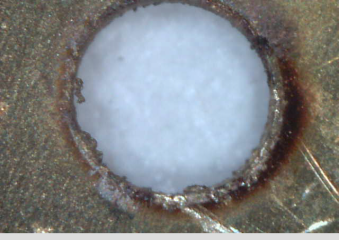

Hole of the watch needle cut by using 50W fine laser.

- Prominent burring of samples around periphery, higher heat affected zone.

- More metal amalgamation upon beam incidence. Improper material removal & more burning.

Hole of the watch needle cut by using 20W fine laser.

- Limited burring of samples, lesser heat affected zone.

- Better sharpness and lesser metal amalgamation after beam incidence. Better material removal and lesser burning.

Listed below are some images of samples after processing. It is observed that post processing only required ultrasonic cleaning for burr removal and eradication of amalgamated metal. A reflective gloss can further be obtained by polishing if necessary.

Conclusion:

The inference is that, the 20W fine laser has better sharpness, lesser heat transfer to the surrounding metal, minor burring and burning of the sample with almost equal cutting time in contrast to that of the 50W fine laser.

This is owed primarily to the fact that the pulse duration of the 20W fine laser is much lesser than its 50W counterpart and as a result, we have a better beam quality with higher pulse energy in the 20W fine laser.