- Have any questions?

- +91 9210626626

- info@markolaser.com

Cloud / Database Integration

Openness with I/O Ports

Data Analysis

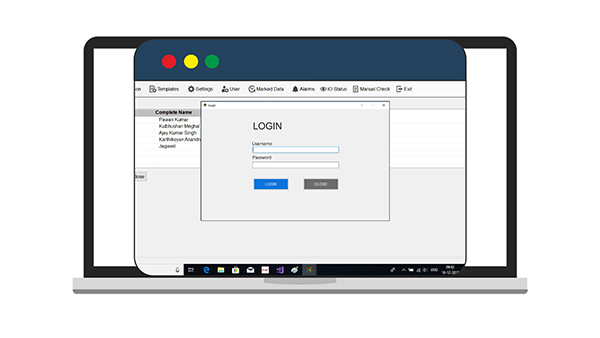

Administration level & Authenticity

Various access levels can be set for operators, plant heads, retailers, vendors, etc.

A unique login can be made for added security and different levels of data to be accessed.

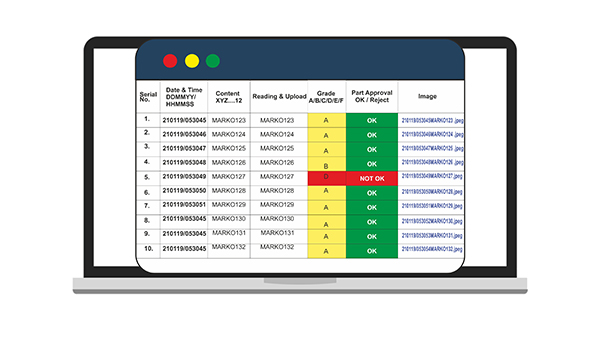

Quality Inspection

The quality of a unique code marked can be scanned and its grade is updated to the server if the laser marking is done.

Managing and tracking the equipment and tools for inspection can be carried out and the collected data can be integrated to the cloud.

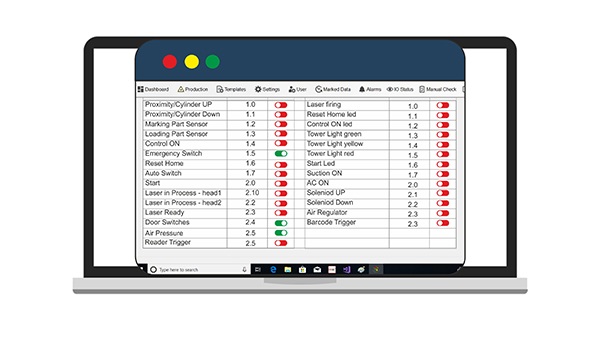

Sensor Control Interface

The sensor control portal gives us the facility to monitor the parameters that we need to activate so that we can get an alarm if there is any emergency.

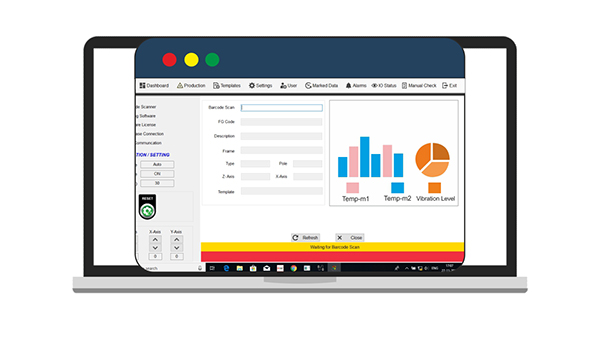

Analysis

An intelligent sensor in combination with Marko-controller and iTRACY makes it possible to collect and monitor the data of the component and machine or systems in real time.

With the analyzed data it is possible to correct errors and help in reducing the consumption of energy due to faults that occurred in the system.

Open Communication

Easy communication with Ethernet, Profibus, Profinet and RS232 etc can be done with our iTRACY platform.

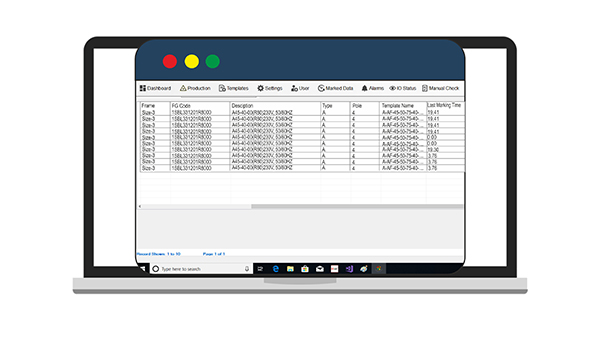

Report Generation

The system provides us the ability to generate reports which contain critical data. The data is further used for analysis of all the different processes and conditions.

Vision System Integration

The vision inspection portal helps in the Integration of the vision system to identify any type of flaw for right inspection and segregation, the integrated vision system helps in easy analysis of production performance.

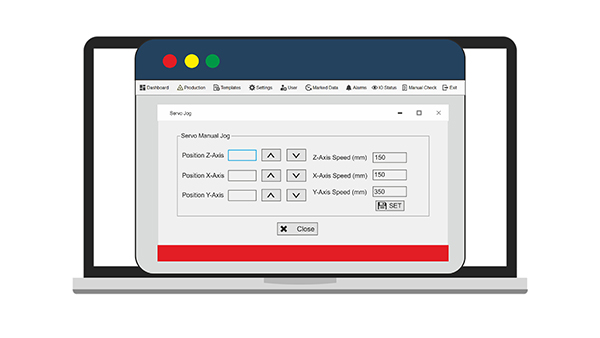

Automation Operation

The automation portal provides a clear visualization for the automation. For better automation, the value of X,Y,Z axis can be set manually. The integrated sensor helps in adjusting X,Y,Z values of the moving parts.

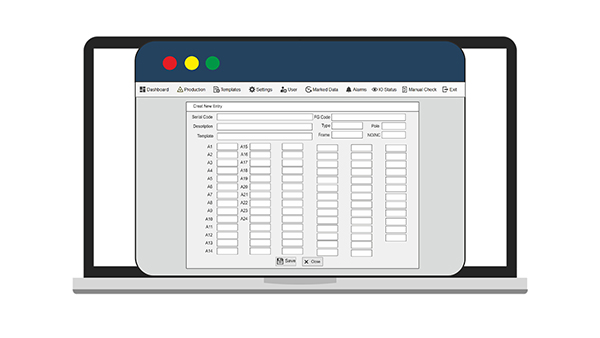

Flexible Customizable Portal

We provide our clients flexibility and an open platform where limitless data can be updated again and the unique code is managed. The data can be later updated to the server/database/cloud.

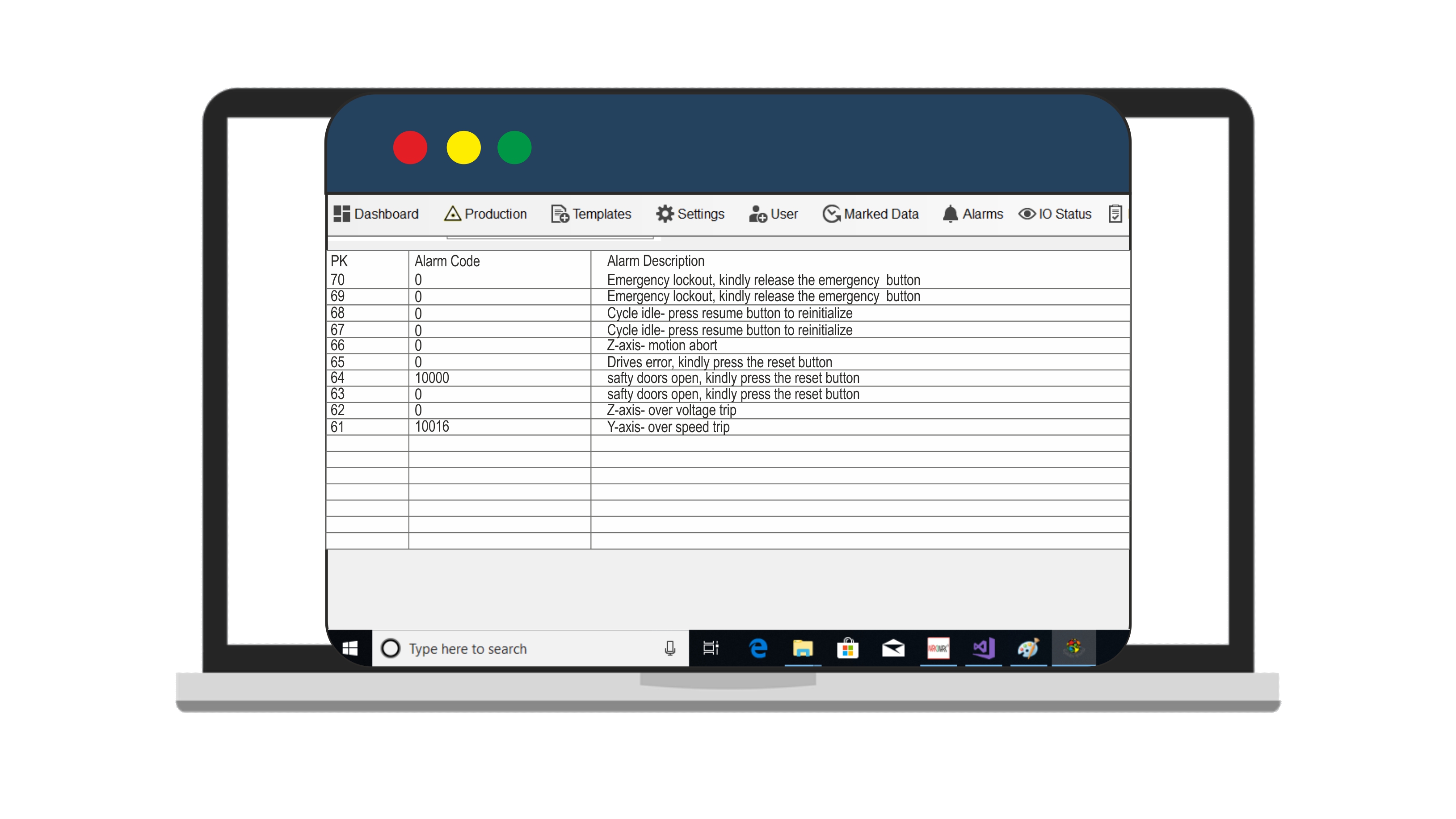

Alarm/Event Management

The custom command can be set according to the requirement related to the production for example, the threshold can be set according to the quality of marking, production outputs. Alerts can be auto sent via email & sms.