Laser marking on auto parts:

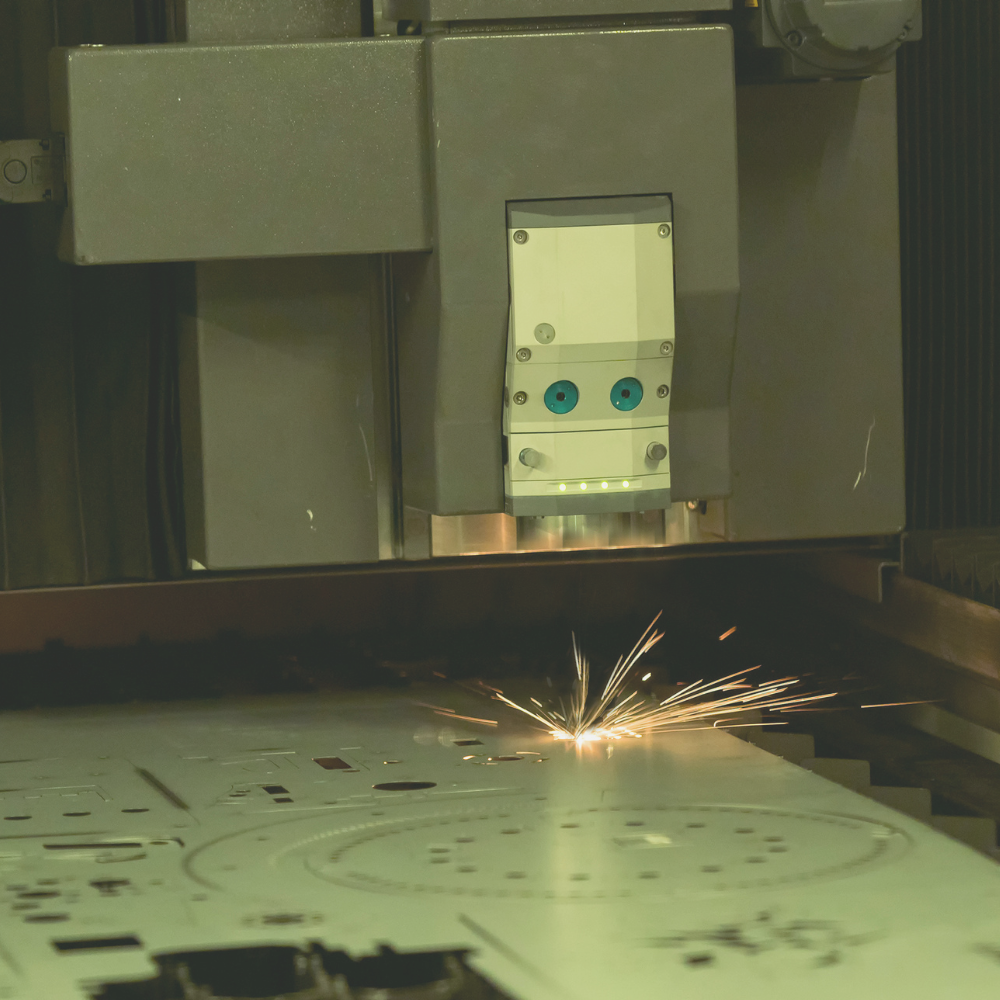

Laser marking is an advanced technology of automobile production, which has been applied to make high-quality car accessories as well as fitting signs for years. In addition to the laser marking technology, laser welding, as well as laser cutting, is also well applied in the automobile industry.

Foaming Laser Marking on Automotive parts

Foaming is a laser marking technique used only on polymers. Laser foaming is carried out by creating a molten burn on the surface. The molten surface creates an atmosphere of foaming gas bubbles. Foam laser marking is usually carried on a polymer which results in a light color.

Some of the key-points of Foaming Laser Marking:

- Used only on polymers

- Produces light & smooth markings

- Material melts, creates foam and gas bubbles

Coloration Laser Marking on Automotive parts metals and plastic

Coloration laser marking is the process of adding color to a polymer or metal by controlling laser and scanner parameters such as pulse frequency, pulse width, power, speed, and more. The coloration on polymer occurs by the foaming process while it occurs via oxidation in metals.

Some of the key-points of Coloration Laser Marking:

- Colorations process is applicable for both metals and plastics.

- The process for coloration varies, depending on your material.

- It creates contrast in both colored and black and white materials.

- Color results are based on an oxidation process.

Sample : Laser marking on Automotive parts

For more details visit us at

Laser marking on the following Metals and plastics is Possible

- Stainless Steel and Common Steel

- Steel alloys

- copper and Aluminum

- Aluminium and copper alloys

- Plastics, such as PA(Nylon), PP, PE, PET, ABS, PVC, etc.

- Natural fibres

- Coated metals

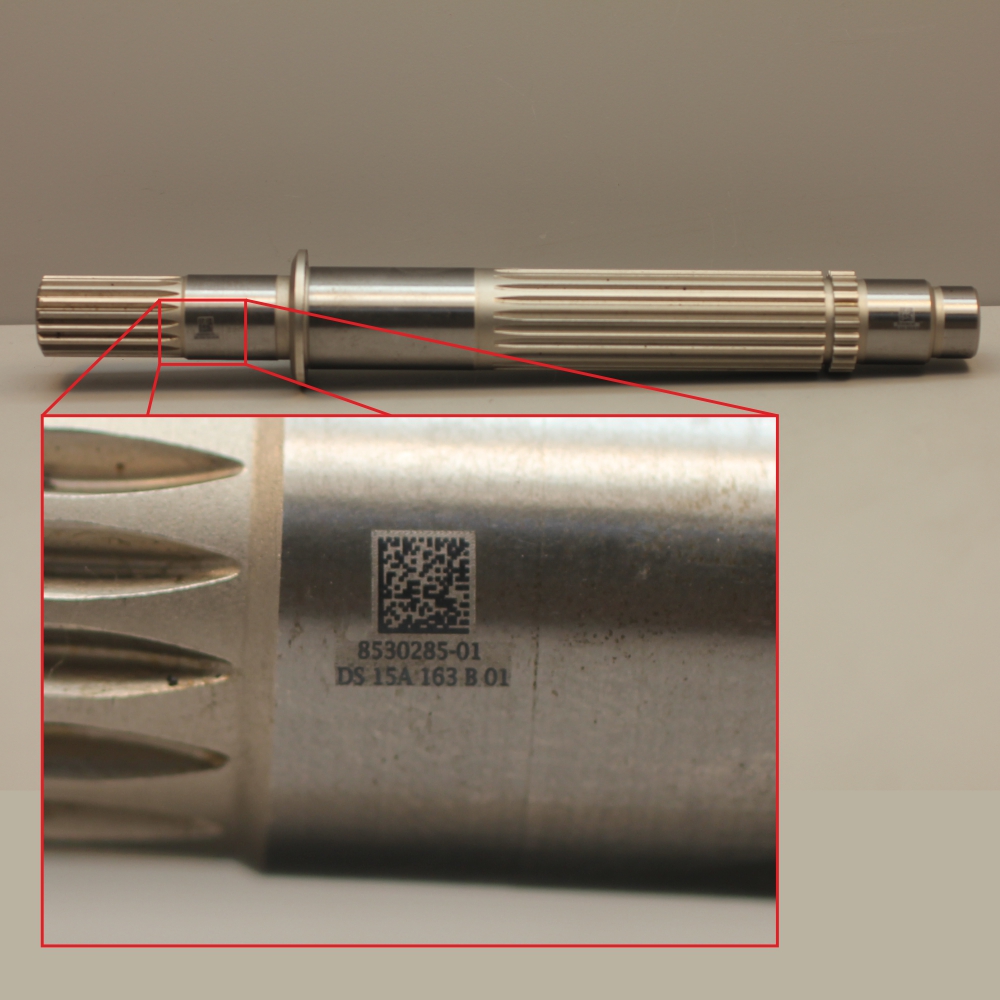

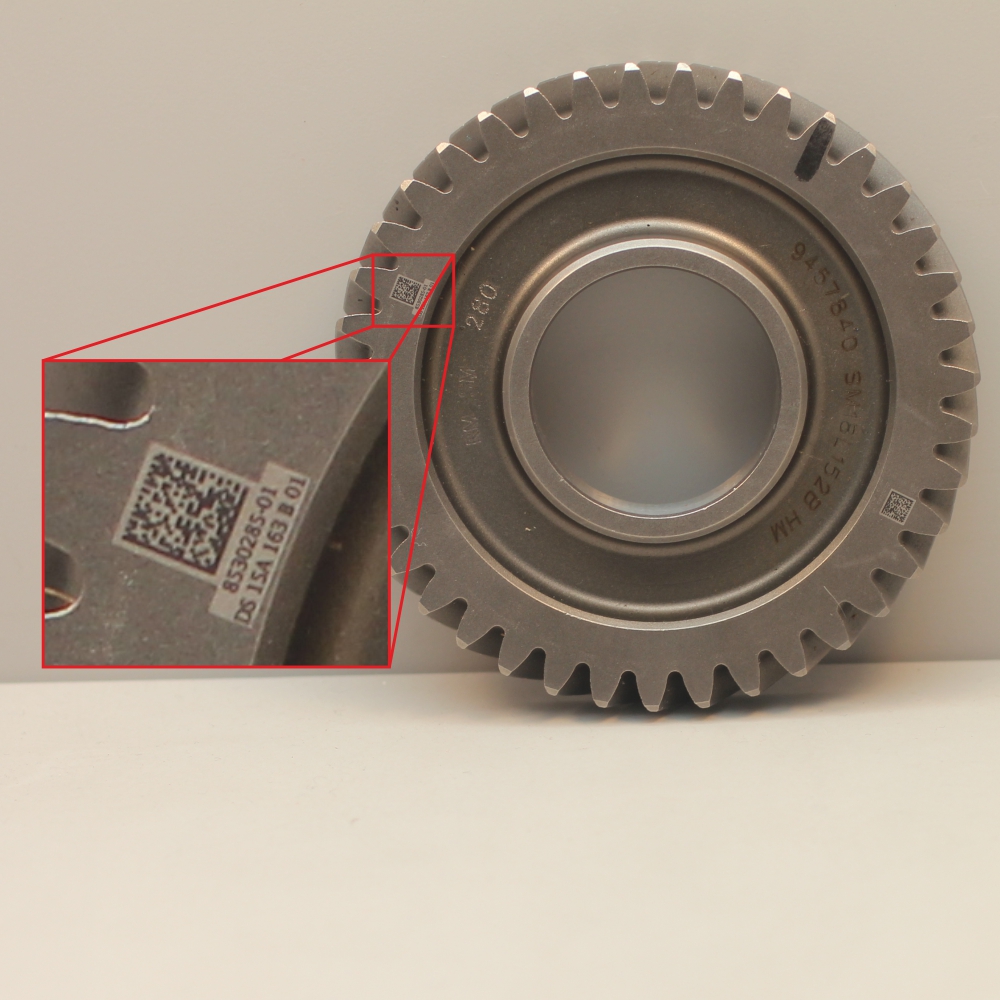

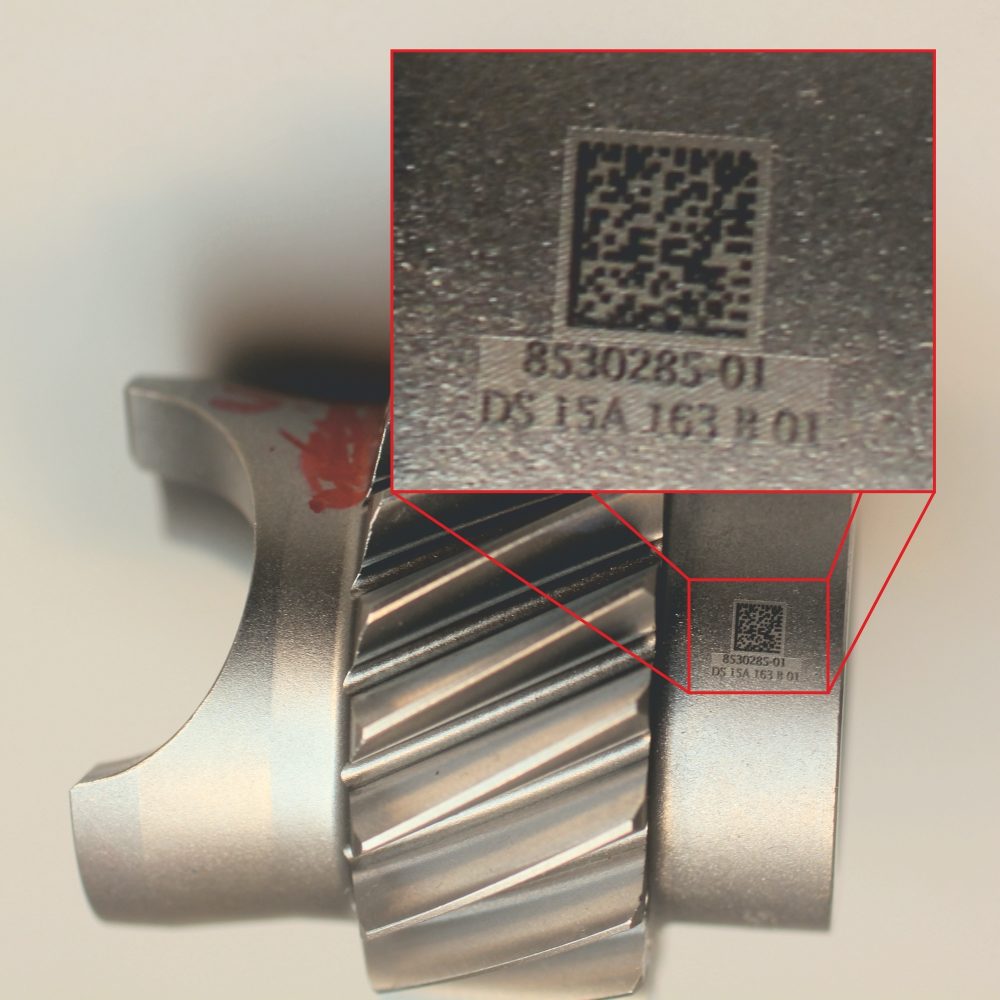

- The applications of laser engraving in the automotive industry is to trace the automotive part like gear or gear assemble with data matrix code i.e DPM, for complete product traceability of that particular part throughout the life cycle until it gets recycled or decomposed. These automotive parts are generally made up of metals and plastics. It may be the internal parts which are needed to be marked with DPM or the Automotive part for decoration for backlight in which we remove the layer of coating from the surface so that when we on the light we can see the button itself glowing

- Laser marking on Speedometer, Tachometer & Indicator for backlite

- Laser paint removal from Power window adjustment buttons for day & night design

- DPM on Engine, Valve, Cylinder

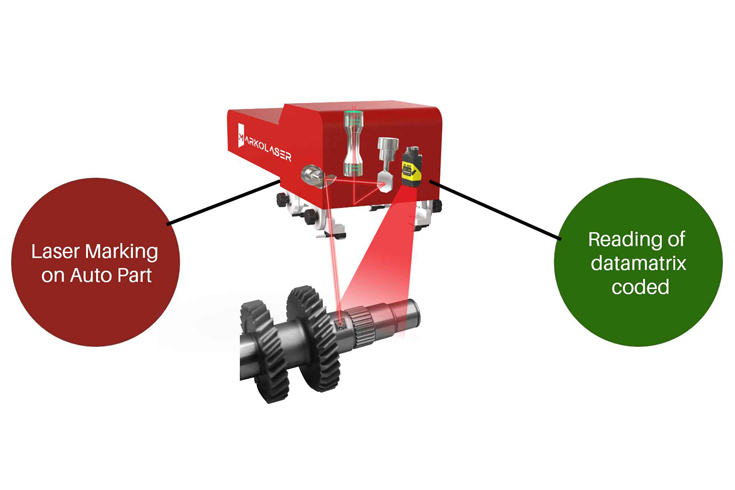

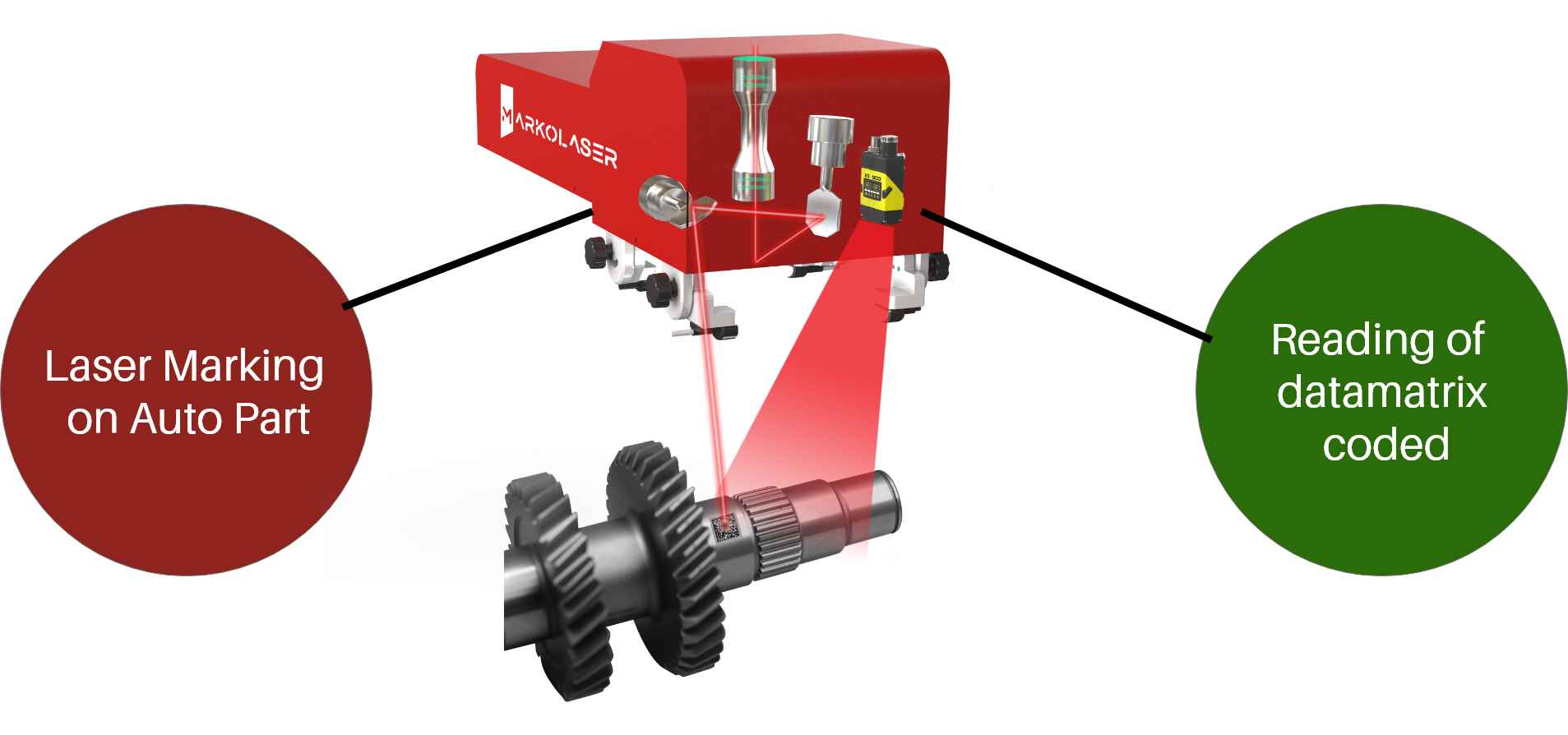

Laser Marking AUTOMATION for Serialization and Traceability on Automotive parts

High Speed ready to use Laser Marking automation. DPM on Automotive part for complete traceability. Data management software to manage the complete data throughout the life cycle. Live data management and product traceability, you will be able to measure the productivity of the worker and production per day

email us: info@markolaser.com

Read More about Automotive Part tracebility(Datamatrix code)

Check-out our website for different technology

| For printing inks and machines requirement | https://www.spinksworld.com/ |

| For precision laser machines requirement | https://www.markolaser.com/ |

| For silicone printing pads requirement | https://www.padprintingpadsonline.com/ |

| For technical and brilliant inks requirement | https://www.farbatechinks.com/ |

| For pad/screen printing inks requirement | https://www.rucoinks.com/ |

| For laser solutions for jewelry industry | https://www.jewelaser.com/ |

| For automotive components decoration | https://www.spinkssoftech.com/ |